Let the fun begin by turning the big bolts tight

A little back story to the story

We received a little present in the mail today. Something that has been a thorn in our side for almost 3 weeks heading on 4. We received clearance to repair this vehicle about 6 weeks ago, we overhauled the gearbox and had bull-bar repair work that was needed. We installed the gearbox, tested everything and everything was good. We then sent it in for the bull-bar repairs, that's where this turned upside down, when arriving at the business to retrieve the vehicle it had no forward gears only reverse gear, it was tightly packed in a cranny corner and seeing that its an 8 ton monstrosity we were left with no option but to hire a towing company and make our problem their problem.

Luckily for us we were able to reverse the Nyala back into the workshop. Removed the gearbox and sent it back to the oaks who repaired it, we outsourced the job because of work overload, made things go a little bit faster, well until it was a disaster.

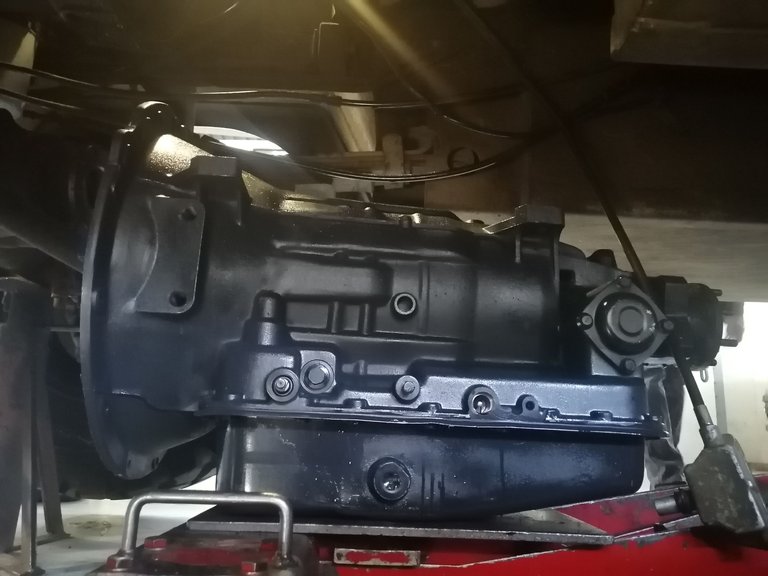

Today was the day we finally got the gearbox back and without much delay We quickly put her back into place! With minor hick-ups along the way

The guide through of what I did

Please keep in mind some steps were left out

If I have to mention everything I would have an extremely long and exhausting post

Ready for installation

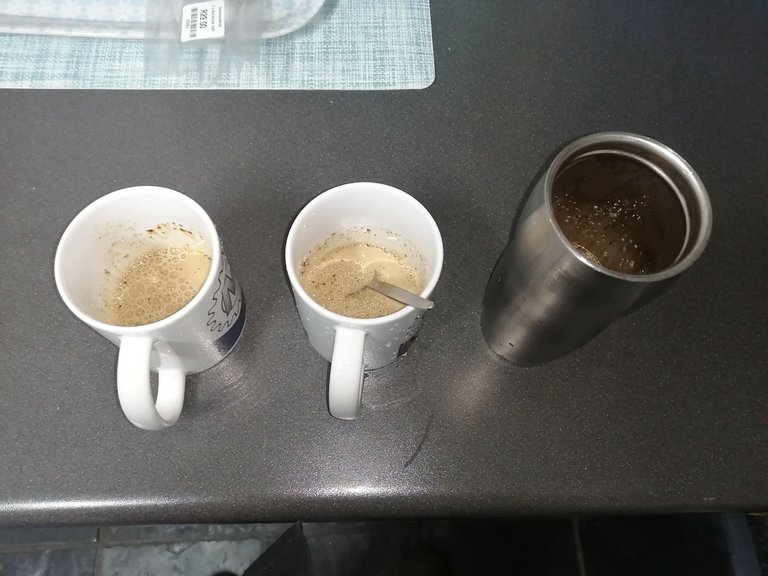

But first I had to make us some coffee, it was a cold night and an even colder morning with the workshop being extra cold and working with metal tools can get quite frosty in the winter! So a coffee was well needed and wanted.

As usual I sort all of the bolts, clean all of the seals or o-rings that might need to be fitted back into place. Double checked if all of the bolts are still in good condition

We also repaired the prop-shafts for this vehicle and gave them a nice coat of new fresh black paint. Yes they are quite big and very heavy.

I am very glad I saw this before installing the gearbox, this would have been a lot harder to repair while the gearbox is mounted to the engine. Even though someone else rebuilt the gearbox for us I don't think they would have knowingly left 2 of the 6 converter nuts stripped. I am assuming that they must have gotten bumped during the courier service.

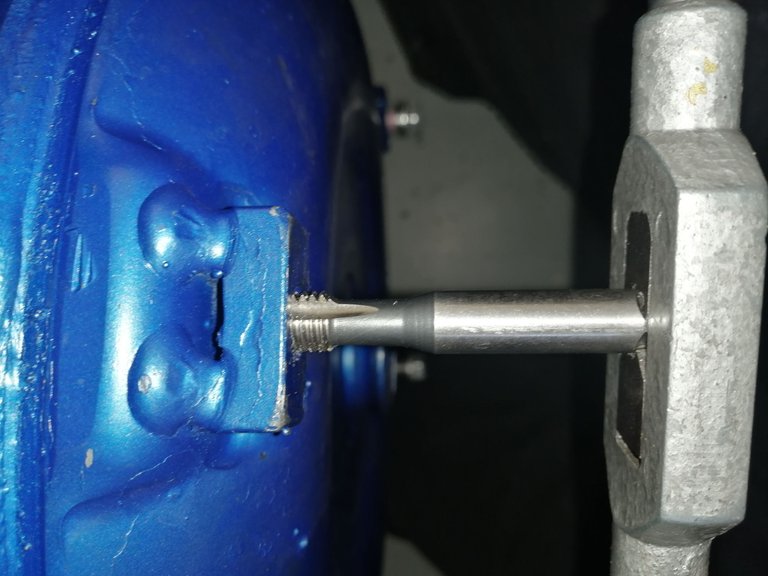

Got the correct taps for the job now its only down to problem solving the problem! Always double check if you have the correct thread pitch and bolt thickness, causing more problems for yourself is never needed.

At first I thought I was going to break the weldings off, because of the thick thread pitch it took quite a little bit off pushing force to get it going in its original thread. Putting a drop of oil on would have made it a bit easier.

Seal off all the extra add-ons to the gearbox properly preventing leaks from happening prematurely and tighten properly to torque specs.

Got the gearbox nice and center placed on the gearbox jack which has a much wider platform meant especially for big gearboxes like this one.

Once the gearbox was jacked high enough I aligned it up perfectly making way for a very clean and easy installation with minimum effort.

Once bolted into place make sure you have entered all of the bolts before torquing one bolt to spec, I feel its better to tighten each one at least a little bit and then torquing all of them.

After I torqued all of the bolts it was safe to remove the jack from underneath the gearbox. Yes this gearbox does not have any mountings, it is held in place by its weight of the engine

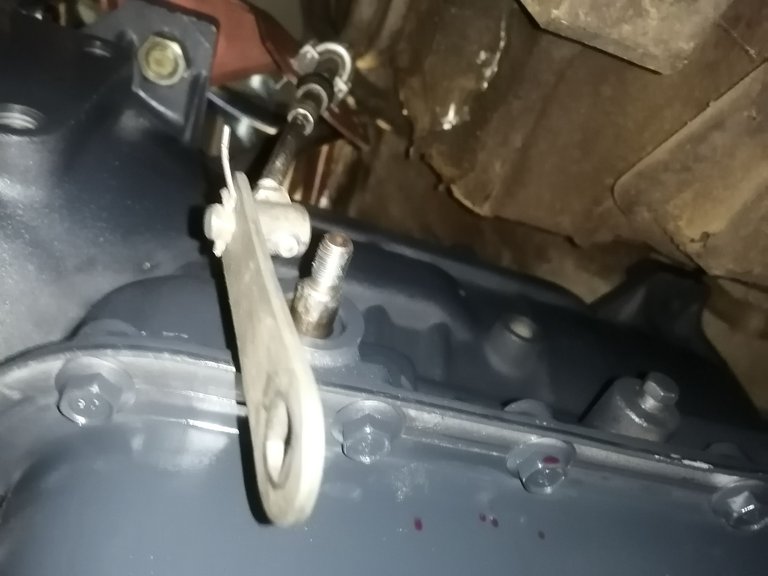

Let the nightmare begin. This is probably the worst and least liked part of working on these vehicles for me personally. I don't mind converter bolts or nuts or entering them. But on this specific vehicle, its really a pain, and its very uncomfortable.

A tiny little hole through which you can bolt the converter to the fly-wheel

Trust me its nerve wrecking, what if the bolts falls out of the socket into the bell-housing. Well if that happens we call it a day. JOKES

Give the final touches to the gearbox, we sometimes joke around putting the jewelry on her, finish it off nicely and everyone is happy. Put in more effort then what you're getting in return.

Add your propeller shafts and we are almost done and dusted with this job, only a few more bolts and nuts to tighten, and believe me the last few nuts and bolts on this job is time consuming. There is only space for a spanner and its tedious work turning and turning on that fine pitch thread, a 0,50 if im not mistaken.

Seeing that its an automatic gearbox we give her some ATF - Automatic Transmission Fluid. Always use the correct oil for the type of box you have, make sure you have the right viscosity and dextrosity (always) It can play a big part in the functionality and longevity off the product you offer.

There we go, We finally arrived at the finish line! Vehicle is now ready to be tested and re-checked for leaks and possible loose bolts.

Always leave your workplace in a good condition, CLEAN UP AFTER YOURSELF!

Make sure to clean your tools and store them in the correct manor and in the correct place when someone else needs the tool they can find it where it is intended to be. Be more aware of how that can affect your overall speed and effectiveness in the workplace.

After all the work was done we took a breather, I made us some fresh coffee, we each had something to snack on. We then proceeded in cleaning up the shop, rearanging the cars in the shop, getting the jobs next in line ready to be worked on.

Preparation is the best weapon!

To everyone who made it this far into my lengthy post Thank you for the read and the support.

If you found this entertaining or educational please consider a re-blog and up-vote

Most of all please leave a comment

Connecting the people of #HIVE across South Africa. #hive

My greetings, @technicalside.

Quite a job you performed, very neat and tidy I would say. With all those details you had to look after, I guess you had to repassed them to make sure everything was under control. Just imagen a nut or a converter bolt had dropped, i guess everything had to be taken down and off.

By the way, I understand that the propeller shafts had to be installed in such a way that they don't produce any vibrations whatsoever, is that so in those heavy duty vehicles?

Reading your answers to @jesustiano, I suppose that those trucks don't have an assigned driver, I mean, any one there who is responsable just to drive them. When this is not the policy, no one cares if there is a leak of any fluid, either coolant, engine or transmission oil. If different, the responsable driver would be more concerned about anything that could be wrong with his assigned truck and would undergo a check list prior to getting it on the road.

Very nice and didactable post.

Take care..

Hi, sorry for the late reply @ogutierrez.

Yes it was quite the job, we still have 2 of the 14 left that we initially got over the last year.. Year and a half... One needs a gearbox job and break drums... And the other one needs both an engine overall which we are busy with, im not the one building the motor, my grandpa is the lucky one their, and the one with the motor needs a gearbox overall aswell.

Back to the topic at hand😂😅 converter nuts.. Yes they can sometimes be a little fiesty, im sure you've been through that situation, knowing all too well about the risky risk of those nuts falling 😂😂☔

Yes 2 of the propshafts.. Hmm how can i say this? They can pull apart.. And if you didnt mark them before pushing the two pieces back together they can be misalligned with each other and can cause a vibration... BUT if you dont pull them apart you should be fine, seeing thay they have no center bearing... So aslong as your two joining flanges are properly placed against each other therr should be no vibration.

As with the assigned driver... Im not going to dig too deep into politics, but the current ruling party of my country, well they simply just dont care, it would blow your mind at how corrupt and bullshitting they are... Not even caring for their own people, feeding them lies to fill their pockets.. We have a serious problem regarding that... I assume that before 1994 these vehicles had assigned drivers.. Or whatever vehicles they had those years. But I am almost cert2they had assigned drivers... But now their is no control what so ever over the police state owned vehicles... Close to my house their is a police depot with atleast 400 brand new vehicles thats been bought and have been standing in the weather for the last 4 to 6 years...

Sorry for the stretched reply... I hope you found the answer you were looking for even though i strayed off topic alot

Hi there @technicalside.

It is quite ok, sometimes we find ourselves so tide-up that we don't find time to do even what we like.

Very true on the proshafts, as lon as you don't pull them apart everything is fine, otherwise vibrations could take place even at low speeds.

Regarding the assigned driver, I believe it happens in most of the departments having to control state cars. Unfortunately that may be one way they, the state, can get away with their way of mishandling things, however it is not our matter to talk about that in this communities, which are for our enjoyment.

Once again, thanks for your post and answer.

Take care..

Hi there. I am just a bit busy.. And struggling with my RC aswell.. But I will get back to you tomorrow or later tonight. Thanks for the feed back Uncle.. Its much appreciated 😎

Now this is a reparation with power, repair something while drinking coffee is the best way to do it, no questions, it just IS. Now I have two questions: How and Why this vehicle needed those repairs, I mean, everything wears down and breaks eventually but my god this vehicle looks like it could go on a zombie apocalypse and remain untouched. So how did it broke down?

Hi there @jesustiano you are correct its suppose to be indestructible? Right?

Well yes if its maintained properly.

It had a cooler hose that was leaking ATF fluid from the transmission.. Seeing that its an automatic gearbox it has an external cooler outside of the gearbox located in front of the radiator, serving the same purpose as a radiator. The hoses leading to and from the gearbox to the cooler were corroded and caused a leak of fluid.

Seeing that automatics take alot of oil it can easily get oil starvation because it operates on oil pressure caused by the rotation of the motor, no oil.. No pressure. And then they clutches can't apply properly causing them to burn.

These vehicles have been neglected for a long time and most were stationary for years, then suddenly one day they were used again, without proper maintenance this caused some problems.. Its the 14th one I worked on in the last 2 years... With 8 or 9 having gearbox issues..

Manuals and automatics

Damm the damages are even less that i would give on any guess, i mean leak of fluid leads to corroding and oxidation and those two can eat an engine or entire vehicle down in no time at all. So at least it wasn't that extensive and could be fixed, sad that they have poor maintenance, with proper one this would have never happened, but at least the damage was focused into specific parts that you can replace, skillfully may I add for what i can look, as not many mechanics knows how to do this level of work.

Hope the owners keep it maintained after this, it would be a loss to see it break down again :(

I sometimes wonder... I think most of them can do this type of work.. But what you say is true... Its just most are lazy.. And its sad to say.. But most people only do this job because they have nothing else to do.. I prefer to do this job.. I absolutely love working on anything mechanical... Given there are some cars id rather not work on... But given the opportunity for making. Money or even helping someone I would more than likely help or sell my time..

Anyhow... They are quite tuff little beasts.. Im sure they would hold for a few years

Hopefully it will now last!!

Come to think of it... I dont think I added the reason why the box failed.. Ill just give it a read through again 😂..

Thnx uncle... Its looking good BTW

Did you add it now? Im really curious on what could make a monster like this vehicle fail, i mean it looks so unbreakable, you know?

Yes we sure did! Added it yesterday. Its still in the shop, currently waiting on clearance to release the vehicle. Its ofcourse state owned 😅👌

Oh so sad its state owned, But at least you got to ride it? I mean, riding this monster sure would be cool :) (Yeah im like a kid with a new toy, sorry)

Ofcourse yes... Well I didn't personally drive in that specific one... But I have driven in some previous ones yes both the manuals and the automatics 😜👌..

They are slow trust me.. Although not that slow... Topping out at a 70-80 km/h on the freeway

70 is fine in vehicles like these, they are heavy and their engines have to put up with them :) and that ain't easy, but damm fine they are, would love to have one on a zombie game, sad is their consume of fuel, it should be huge :S