Well hello there Hivers! It's been a while since I posted in #hivemotors, well its only been a week but it sure feels like it has been a month!

Lets get into the technical post of the week!

So recently we received a car from Ford that has gearbox issues, it had a little whining noise or well that's what the customer complained about. We actually rebuilt three different gearboxes for this car and every time it has the same noise. Okay when I say a noise I really mean like nothing at all the noise that the customer heard the first time was a bearing that collapsed thus giving off a heavy grind when you start the vehicle, almost like a rumble sound. I get that, that needs to be fixed, but the noise I am referring to is so light you can barely hear it, even the little 3 cylinder motor is louder than that, and let me tell you folks that noise we will never get out because that is the way the gearbox was designed.

What the customer doesn't understand is that we can only build according to factory standards, sooooo this means if the box is built with that little whining noise that is what you are going to get. After a long struggle and countless hours wasted for nothing we reversed the claim and told Ford to fit a new gearbox. Yes a brand new gearbox, the problem is that the customer will still have that whining noise, or perhaps not maybe they upgraded the gearbox since then although I highly doubt it because it is a 2016 or 2018 model.

Once we got the new gearbox we fitted it for them with the hopes of the whining noise being gone. (PS. Its not though, I suppose we have another smart client. As usual.)

The Fitting Process.

Okay, yes I know there's a lot of preparation and missed steps up until this point. I'm going to get right into it.

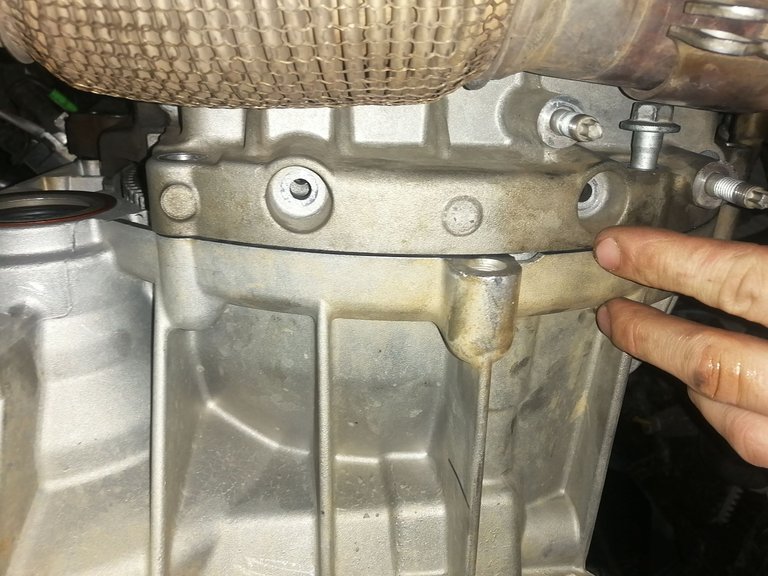

What I'm showing in the first picture is more or less how the joining of the bell-housing to the side of the motor should look before bolting down a gearbox. #humble brag but one man alone, lining the gearbox up perfectly!

Now that's something

Even if I have to give it to myself.

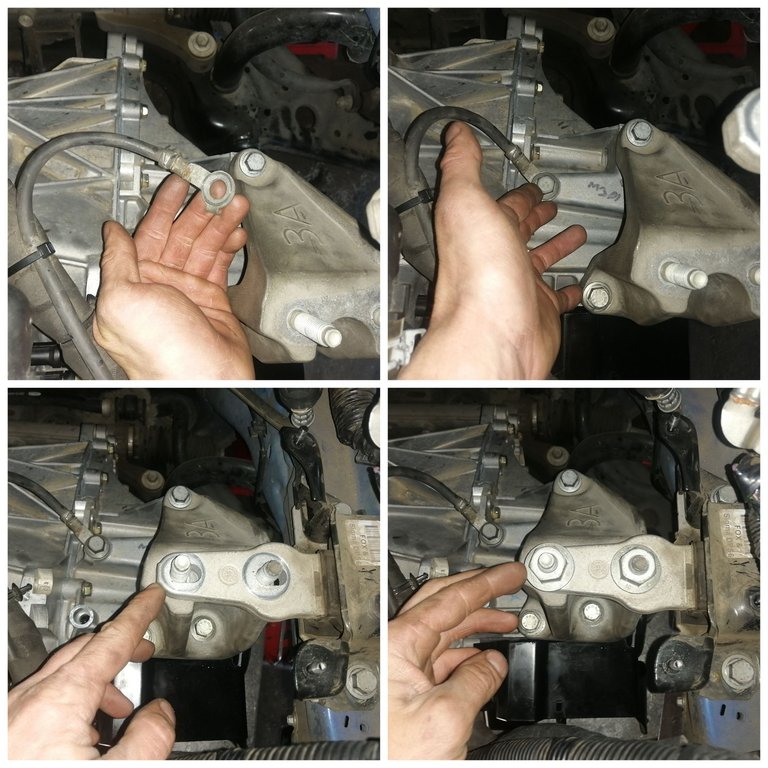

The moment I bolted down the bell-housing, even before I secured the engine mountings to the chassis. I absolutely had to bolt this exhaust bracket hanging in my face.

Just look at them "Ford Engineers" placing a bolt behind that bracket. I mean was it really necessary? Was it perhaps done on purpose😆 Maybe cause some stupid bloak somewhere out there to force wedge the gearbox out and ending up breaking it.

Nah jokes aside, this is actually very important and the problem is that many people don't bolt the exhaust bracket back into place again after performing work on the vehicle. And this causes vibrations that end up cracking the exhaust manifold. And people wonder why their cars fail pre maturely.

It's because of poor workmanship.

Upper Gearbox Mounting.

Finally we can secure the engine and gearbox safely to the chassis of the vehicle.

Get that big mounting, yes the biggest one. Bolt it in place with the three big bolts, yes those ones. Heh Heh Heh🤣

In the picture you can see the motor hanging on the chain with a nice piece of metal holding it all up there.

- Bolt down the top gearbox mounting

- While you're at it add the earth wire to the gearbox as well, seeing that you are working in that vicinity.

- Guide the studs on the mounting through the other half of the mounting.

- Bolt it down tight and secure.

- I should probably mention that I am using a automobile jack to move the gearbox up and down to get it lined up correctly with the mounting.

Lower Gearbox Mounting

Once the top is secured and the motor is hanging around in the engine bay I then go back to the underside of the vehicle and finish up most of the work, and then return to finish everything above in the engine bay.

- Grab the lower gearbox mounting a long with the bolts. Take note they differ in length.

The Lower gearbox mounting place is located just below the differential where the right side CV-Joint_ joins in with the gearbox.

- Bolt it into place on the gearbox and then continue to bolt it to the sub-frame.

- If you have the right bolts you really cant mix them up, so it's easy to figure.

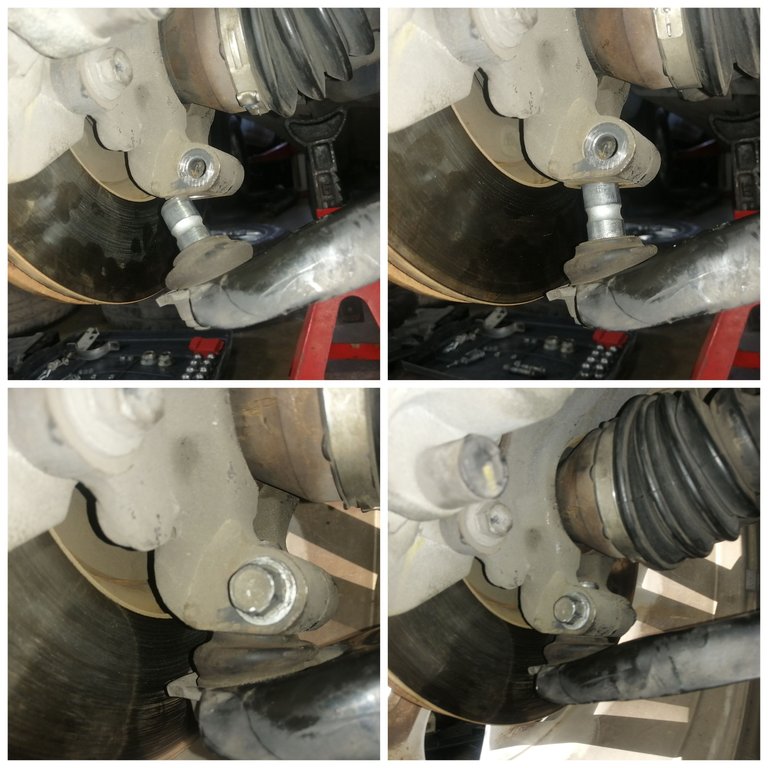

The Side-shafts.

Now this is probably a personal thing, I hate re-fitting CV Joints. I don't know why but I just do, and its not even a hard task to do but everytime I have to refit them I give this sulky sigh.

It must have been Volkswagen with the frikkin 12 bolt down CV's.

Anyways I gotta do what I gotta do ey.

I tend to clean the spoked shafts of nicely before refitting them, seeing that we did gearbox related work anything we overstep or miss might impact the longevity of the gearbox.

- Clean off nicely and give a droplet of oil to make fitment easier.

- Right side just slides in.

- Left side has a little cir-clip that prevents it from popping out.

- They also differ in length so distinguishing would be quite easy.

Indication of how the right Cv joint will enter the gearbox. This means you are halfway there, grab a copper hammer or even a rubber hammer or if you are made from metal give it a bump with you palm or one of the other methods. Just get it in there nicely over the seal.

The CV's are in now you got to bolt down the right side Cv where the bearing is located. This is why the right side Cv doesn't have a cir-clip on the spoked point is because you bolt it down so it's already secured into place.

Food for Thought.

A question to the engineers. Okay I think you guys don't get it but bearings do spin yes? And at very high speeds. So what if somehow this bearing fails, and someday it will its very exposed. And when a bearing fails it eventually seizes up, and that's a big bearing and trust me if seen smaller bearings causing big lockups.

The reason why this bothers me is because you bolt it down the back of the motor so if it does decide its going to seize up it might blow your whole motor away. The chances of that happening are slim but there none the less.

Everything on the Wheel Hub

Okay the CV's are fitted to the gearbox, but you now have to get the other half into the wheel hub.

Its an irritating task and one that requires both hands. Sadly taking photos like that is hard.

I use a old screw driver and press it in between the brake-pad, this will only work if it's ventilated brake discs.

The screw driver prevents the wheel from turning so that you can tighten the big nut onto the Cv joint.

Tighten with leverage or using an air-tool. That nut is very important, remember it rotates with the wheel constantly.

Lastly on the wheel hub you have the lower ball joint to get into place, heh heh heeee. Now these can be devilish sometime, the refitting is forgiving.

The removal, much less so.

Lining it up as straight and as perfect as you can get it and then adding a droplet of oil onto it will make it pop into place the easiest.

Then bolt is down.

The Gearbox links

Again these can be devilish to remove, a lot of people tend to break them either with removal or refitment. Take you time to figure them out, but you really can not get it wrong.

One joins in on the gearbox much like a balljoint and the other link just pushed over a shaft that it pulls.

Mount the cables onto the black box connected to the gearbox.

Close encasing.

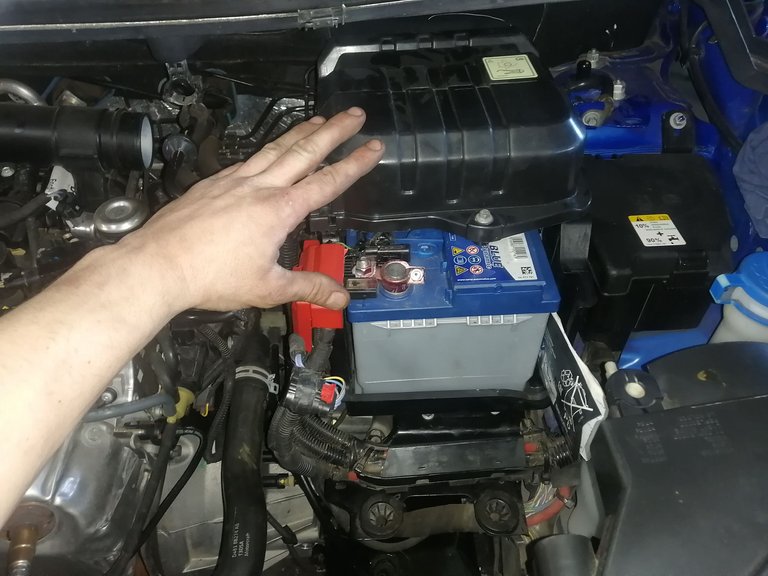

Finishing up top.

Refit you battery box a long with the battery into place, Its safe to say that you can now reconnect the power to the vehicle

- Fit battery box

- Fit battery

- Mount the vehicle's PCM into place.

- Reconnect the power to the vehicle.

Last but not least fitting the airbox should usually be the last thing to refit and also the first thing to remove.

Get it back into place without breaking the mounting ins off, also something that a lot of people struggle with. Luckily this one is still in one piece.

- Join the airintake pipe with the motor.

- Clamp it down on both sides. The airbox side and motor side

- Connect the air intake sensor plug back into place.

The bluest blue that I have ever seen on a vehicle and that on a Ford as well! Known for them blues eyyy.

Check the picture above. Even the battery has blue in it, this must have been some blue Ford limited edition.

She is all done and dusted, well not dusted by the looks of the bonnet. Only one last part we are waiting for from Ford and that's the reverse light switch, but for now we can test drive it.

To everyone who made it this far into my post Thank you for the read and the support.

If you found this entertaining or educational please consider a re-blog and up-vote.

Most of all please leave a input in the comments below, whether is good or bad critic I would like to know, whether its your opinion or your way of doing things in a different manner I would like.

Connecting the people of #HIVE across South Africa. #hive

The rewards earned on this comment will go directly to the people( @technicalside ) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

I am not an expert mechanic, my father is, and I always remember hearing that Fords often have this type of problem with their gearboxes, and there are some difficult customers who prefer to save what they think, rather than spend a little more and have the car perfectly fixed. Good thing you were able to come to an agreement to fit a new box.

I hope that the last missing part arrives soon and this Ford will be on the road to success.

Well I would say its safe to assume that Ford's have a lot of problems xD... No hate to the vehicle brand,,, I drive a Ford myself!

Lets use my car as an example.. I changed the rear main seal on the crank about 3.. maybe 4 months ago! Its leaking again.. now thats a ford,,, if it doesn't leak you dont have a ford...

no jokes aside I might have only gotten a bad seal or something but other than that the vehicle is running smoothly!

That last part arrived not long after I shared the post!

I hope the customer gets a Nice ride with the new Gearbox, I thought 2 things reading your post. First si that we have to understand that an old car is very rare to be perfect You have to get used to some noises of course after checking out what si the cause, and second that those kinds of car are not mechanic friendly, maybe is the designers saving space but it's never easy to get to some parts

You are right. Haha the problem is explaining that to the customer in a non offensive way xD.. But luckily we were able to come to some sort of agreement. So everything is good now, and the client is more than happy.

eventhough he had to wait some time for the gearbox.

Good explanation in these days the most difficult life in the world to be seem engineer's because they work much difficult but get rewards very short you show very good and all the parts I hope everyone will get lesson from this post

thanks buddd