My forge has arrived, yay! I finally can have some fun. But first of all, I needed to clear the garage to make large clean and safe place to forge. It took several days to clear out all the clutter that was piling up for a while. I did not rush things as I was busy with other stuffs around the house.

My apron

I bought this Crane punching bag at a local Aldi store several years ago, the straps were rotten due to moisture so I decided to cut it open and recover the outer shell (false leather) to make an apron, what I discovered inside shocked me, not only there were offcuts of fabrics and leather (that was a score for me as a diyer) but there was also a lot of filthy dirt and worse of all are heaps of sharp utility knife blades 😱 as seen on my recent tweet:

Anyway, no one got hurt and Aldi is investigating it, so they say at least.

My first knife

For my first small learning project, I wanted to make a knife from an old rusty file. With a pencil, I drew the outline of my knife on it so I could cut it later on.

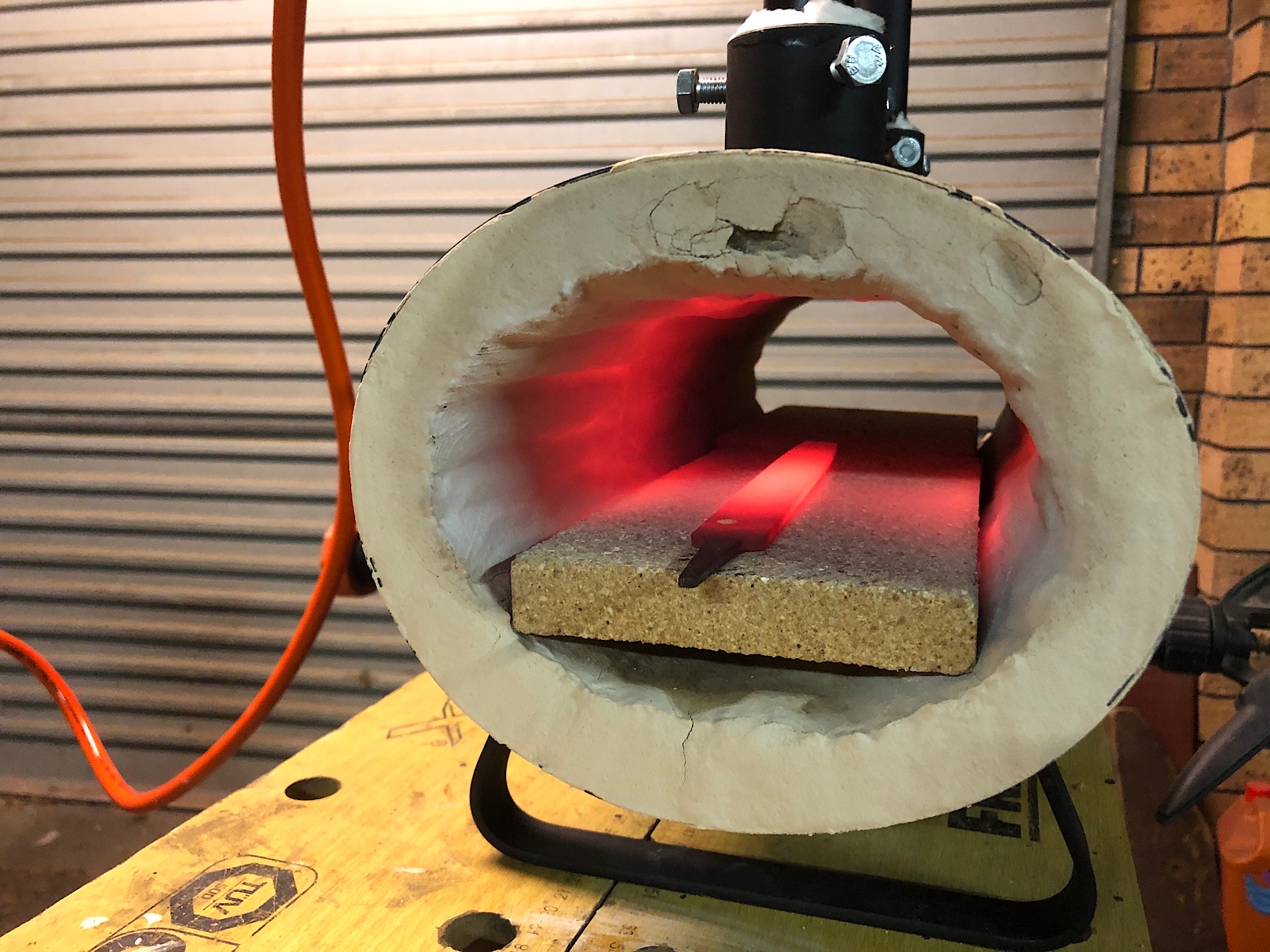

Next step is to anneal (soften) the steel, so I brought it up to a bright red color and let it slowly cool down inside the forge.

It was then soft enough for me to easily cut out a rough shape using an angle grinder. The spark's pattern tells confirms the high carbon content of the steel which means I will be able to harden it so it can hold an edge.

With a round file, I fine tuned the rounded areas and removed any sharp edged created from the grinder.

After making the final shape of the knife with a belt sander, I started the heat treatment to harden the steel. The knife was place in the forge and brought up to a temperature high enough for it to not stick to a magnet anymore. Once that state achieve, I dunk the whole knife into a container of canola oil to quench it (bring its temperature down quickly). This process makes the steel very hard but it will be brittle, like glass. So the next step was to temper it to soften it just a little bit, enough so that it won't chip but not too much so that it would bend. Sorry, I could not take photos of the process as it needed fast timing.

As the steel was cooling down, I started to make the handle from a piece of hardwood flooring.

The two wooden scales were then epoxied to the blade's tang. There start all the rookie mistakes:

- I should have cut the scale thinner because it was a pain to get them to size afterwards.

- I should have sanded the scale front (blade side) before too...

But everything went well and here is the end result. I also burned the wood and finished it with some oil finish that contains tung oil

I love the texture from the file and left it there as I thought it looks great.

The knife feels well in my hand, I'm pretty happy with this first attempt and learned a lot from it.

Here is a photo showing the texture on the spine of the knife

The tongs

When doing the heat treatment of my DIY knife above, I was using a pair of short pliers and it was getting quite hot. So this morning, I thought I would do my first real forging project: making a pair of blade holding tongs. I bought a cheap piece of rebar from a Bunnings and cut two sections of 50 cm long.

My son came to help me forge the rebar, this was the first time using my homemade rail anvil and it was working very well!

It took me a bit over 2 hours to finish the tongs, that was more difficult than I expected. Using a gas forge has some drawback, the torch is heating a large area of the material and it's difficult to keep everything straight when you only need to bend the tip. I need a pair of leg vice or practice some more.

In the end, the tongs look ugly as hell, no symmetry what so ever but you know what...

... they do work! Eureka! 🥳

The main issues I encountered in this project were:

- it was difficult to isolate the heat when using a gas forge, I ended up bending way more area than I wanted

- I went too thin too early and when I flattened the area where the two tongs are connecting to each other, they were very thin and I was worried they would bend during use.

To be safe, I decided to harden the tongs. Rebar are low carbon steel so they don't harden very well and would make awful knives that would need constant resharpening. But they can still be hardened to some degree, better than in their mild state and any level harder is still better for me in the current situation. It did seem to work, I could pick and lift up my largest file with no problem.

Not too shabby 😅 , what do you guys think?

Vote for my witness

On Hive, Witnesses are playing the important role of providing a performant and safe network for all of us. You have the power to choose 30 trusty witnesses to package transactions and sign the blocks that will go in the Hive blockchain. Vote for me via HiveSigner to support my work for the community.

I would say very good first job. if I can suggest ... much higher bevel, ricasso closer to the handle, an extra pin closer to the cutting edge otherwise the handle can open.

A greeting, nicola

You are right in all points, I only noticed them too late 😂. As for the bevel, I did that one on purpose though, I wanted this geometry for strength as I will use it for some wood carving where I need to split a flat area of the surface of the wood. But this might not work as it could not bite deep enough, will see

When you grind the edge, try to avoid a inverted shape. I know, its easily done with a round grinding stone, but it makes a better knife if it has a V or even a slight U shape.

But over all not bad for a beginning. I like it how you kept some of the file pattern, kinda cool. :)

Thank you 😊

What do you mean by inverted shape? You mean rounded bevel? If so then I see what you mean. I tried keeping it flat as possible on the belt sander but without a jig it was difficult to keep the angle

Sorry, inverted is probably not the right word. I mean concave, like hollowed out. It looks a bit like that on the photo. It works at first, but is not good over time.

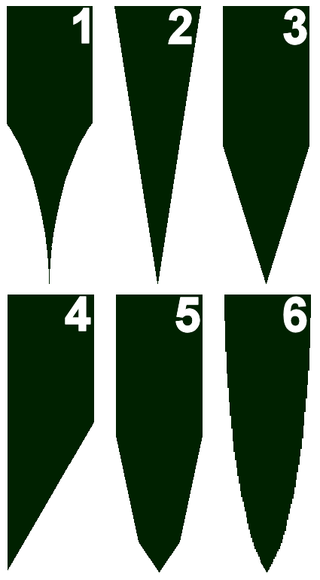

This is what I mean:

1 - better not

2+3 - ok, depending on purpose

4 - japanese, basically the same as 2+3

5 - might as well go all the way for 6

6 - best

6 is, however, taking the most work and time to do. But it pays with stability and lasting sharpness.

Ah ok. Mine is actually like 5. I think it’s the light that makes it looks like concave. It’s actually a hybrid between 5 and 6 lol

You’re way ahead of me! Great job!!! When the SHTF, you’ll have a real, useful skill.

I’m stuck at the heat stage...don’t have my yummy tools yet.

Old chunk of thrown away steel:

The basic shape:

!BEER

Nice shape!

As for heating, you could use a small portable propane bottle with a good full flame burner. Mapp gas would be even better. It would take longer but you could save time by heating just the cutting edge.

I'm hoping to use charcoal, old school style. (Can be made if supply shortage)

Working on converting this old barbecue:

Nice! It will work just need to work on the air intake

This is amazing! You made so much progress in such a short time! Now you could travel back through Time Machine back to a village! You could disguise as a hammersmith!

Very impressive!

Cheers.

Hey thanks 🙏

What do you mean travel back in time? Aren’t we in the middle age???? 🤣

Oh! Yes. But I care from other planet and dimension! So, it’s all very confusing for me! LoL

Impressive work. Hardwork bears fruit. I like the knife you made very precisely.

Thank you

As Doug Mecaida from Forged in Fire would say, "It will keal!" Pretty cool turning a file into a knife. You can file and cut with that HA HA. Makes one pretty handy knife I think.

Hahahaha Forged In Fire has been my lullaby lately lol.

Yea, I can cut my nails and file them with it lol. Kidding, the file was too old and was not sharp and on top of that I sanded it down a bit to make it shiny. Maybe I should make another knife with a brand new file lol

Cool! Maybe one day I will see you on the show :-).

Maybe, if it they can recruit smiths from Australia :-D

The tongs aren't ugly they're "rustic" ;D

The file knife looks really cool with the pattern left on it :)

Hehehe, thanks :-)

Hi,

Awesome Blacksmithing work!!! I have a friend that Forages metal knives, always an experience to watch them bend Mental!

I was reading an old post https://peakd.com/vn-meetup/@thethor1122/2nd-meetup-steemit-vietnam-successfully . I see you were part of a Vietnam Meet up for steem. I am trying to build a Vietnam community here on HIVE. Currently, I am based in Danang and start this HIVE group https://peakd.com/c/hive-147058/trending for HIVE Vietnam.

Where are you located? Do you know a lot of Vietnamese that use HIVE?

Hey there. Thanks

I attended that meetup remotely as I'm based in Australia. We also used to have a group called Team VN when on Steem. But most are now inactive.

Thanks for the reply friend!

I hope you are faring well in Australia as well.

I did look up some the other people in that list that I see most of them are in active is about 2018, Perhaps because the graduate school and Forgot about it? Either way super cool to know that you are out there. :D If you know any other Vietnamese who are on HIVE feel free to send them the link.

Thank you freind.

Very cool, I'm jealous of your workshop setup. And disturbingly this isn't the first time I've heard about random junk sold inside punching bags :(

You should see my wood working setup too. I have way too many tools hahaha.

That reminds me that I have shown many photos of my backyard but none of my workshop setup. I should clean up and take some shots.

As for the punch bag, I’m glad I didn’t injured myself when diving my hands inside to salvage useable pieces of leather or even before when punching and kicking the bag.

View or trade

BEER.Hey @quochuy, here is a little bit of

BEERfrom @definethedollar for you. Enjoy it!Learn how to earn FREE BEER each day by staking your

BEER.Really good job. And be careful please! I think it is dangerous.

Chú đa tài thực sự, hết làm sáo, làm vườn, làm công nghệ rồi thấy làm đủ luôn😅

😝 vì COVID, được làm việc ở nhà nên có nhiêu thời gian tò mò