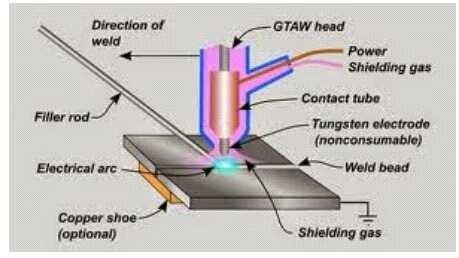

The term GTAW (Gas tungsten arc welding) comes from America while TIG (Tungsten Inert Gas) comes from Europe, which has the same sense that is the type of electric welding that uses electrodes not consumed. These electrodes are only used to generate an electric arc.

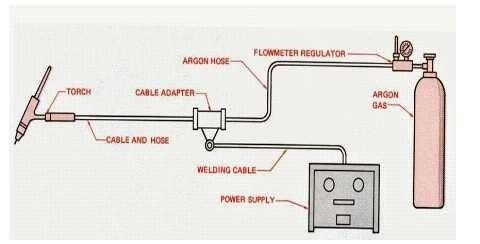

Additive material is filler (rod), to prevent oxidation used noble gases (such as Argon, Helium, Ferron) and carbon dioxide as a protected gas. This type of welding can be used with or without additives. The above sketch shows the complete implementation of GTAW welding. The process uses protected gas to prevent oxidation of hot welds. To produce an unreachable flame arc made of tungsten metal or its alloy of very high melting point.

The flame arc is generated from the electric current through the conductor and ionizes the protective gas. The arc occurs between the tip of the tungsten electrode with the parent material. The resulting heat arc directly melts the parent metal and also the weld metal in the form of welding wire, the use of welding wire is not always implemented, if only necessary as a metal enhancer. Thawing of welding wire is carried out at the end of the welding crater while the pouring process runs

#project99day#day13

@alfajrisyariff