Hey folks!

Last week I shared the fifth blog post of our "Origins" series, where we document the journey of building an apparel business.

As promised, I'll be sharing one every week, so here goes #6! Let me know what you think!

This post was originally published on Medium and weardulo.com.

Origins #6 — Fabric Samples

Organisation and processes around creating our first batch of samples.

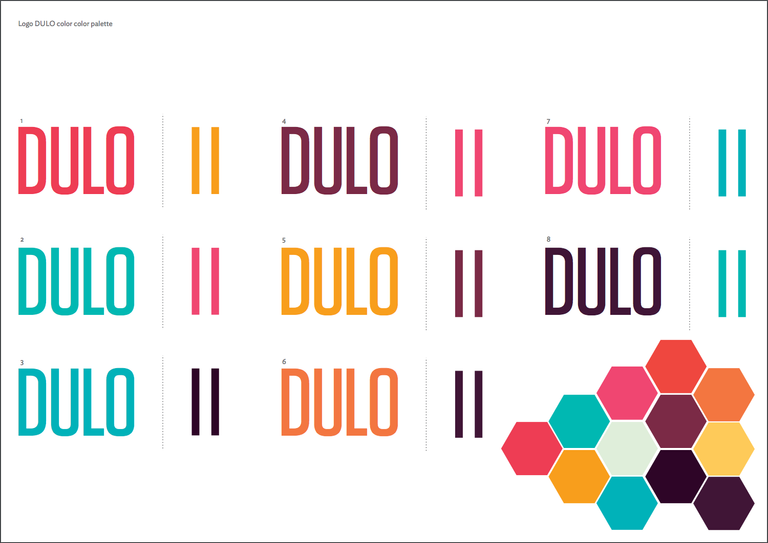

Once we finalised the name, logo, website domain and social media handle, the next step was to get the branding, which included the logo and the materials that will go with the shirts, done by a professional. Most important of all was to finalise the designs for a logo (both the logotype ‘DULO’ and the logo mark ‘||’) as well as a colour palette. From those two we would proceed with the labels, tags and boxes.

We got in contact with a designer back home, that Marin previously worked with and knew he would do a great job. We sent him a brief outlining our vision, brand values and mockups of the assets needed. After a few discussions and iterations we decided on a font, a design for the logos, and the colours.

Our initial vision for the brand was to have a very clean and stylish look and we were considering black and white to be the main colours. However, after we received some great recommendations from our designer, we saw that attaching more colour variety to the brand would provide us with more opportunities for the future.

Then, if we decide to add more products to our range we would not be limited by two colours. Having a colour palette would also help us stay consistent across the different platforms.

In the meantime, our manufacturing partners were iterating through a range of materials that might be appropriate for the first batch of shirts. They sent us pictures of possible fabrics and we narrowed it down to a few that we asked to be sent physically to us. We wanted to touch and feel the fabric and chose the most appropriate one for the first batch. Once we sent the designs, they also went ahead and created the label that would go on the shirt.

The idea was to put together the various pieces, in order to have a rather complete product for the first batch of samples, before we plan our second trip to see them in person and give them to friends and family, which would be our first test group. We knew the fabric would be the most important variable of the whole product, so we have planned a few rounds of iterations, before we actually go to market. This would give us the ability to change and adapt the product a few times, have as many people as we can test it and bring it to market in a quality that we can rave about and proudly wear it ourselves.

Starting to get the product out there, even samples of it, would also enable us to start creating content and branding around it, before we actually start selling it.

The marketing strategy and brand vision was also falling into place and things were becoming clear as to what we envision the company to be in the long run.

Thank you for reading! Drop down any comments you might have 👍

For the latest posts, visit weardulo.com

Congratulations @julian.samarjiev! You received a personal award!

Click here to view your Board

Congratulations @julian.samarjiev! You received a personal award!

You can view your badges on your Steem Board and compare to others on the Steem Ranking

Vote for @Steemitboard as a witness to get one more award and increased upvotes!