Last year the deer 9x decimated my Green beans,and i thought about getting a greenhouse. I have thought about it to a lesser extent whenever there is a frost, and more so a frost with tropical storm strength winds when it becomes nearly impossible to lay out the tarps-but extending the harvest maybe a few weeks isn't worth the expense. I also have a banana growing in zone [ahem, cold], so that means digging it up every fall and bringing it inside-and would consider doing the same with oranges if not for cats. So more reason to look into a greenhouse.

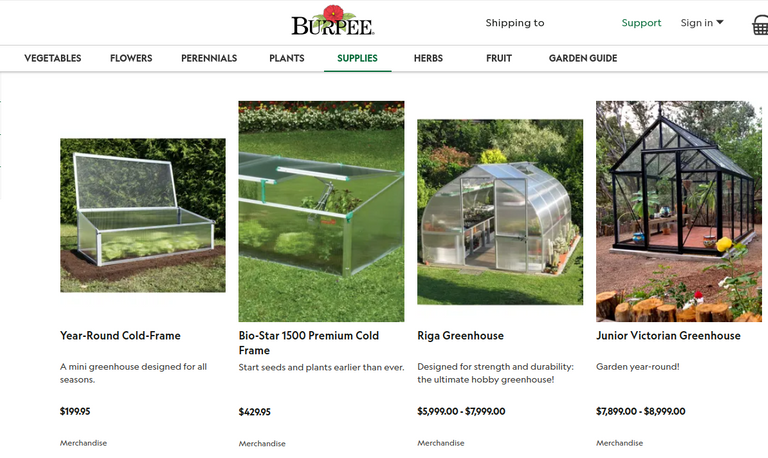

And truth be told,the commercial ones already pre-built aren't really a value for the home gardener. I mean they could be if you are in the business of selling plants that you grow from seed, or have a nice contract. And being in the nursery business could be a regulatory nightmare per reason of pest control.

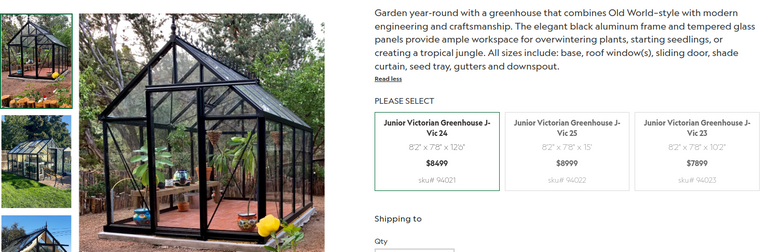

But for the home garden, spending $8000 to grow a few green beans in a tiny space is kind of retarded at least for people who care about budgets. You could buy about 2000-3000 lbs of fresh organic beans from the supermarket, and presumably more if you can buy them wholesale.

So um, yeah, I could keep the deer out with a nice fence for less than one. Might just be cheaper to buy land in Florida or texas, and go on vacation there whenever the expected harvest season is. And I would need like 36 of these to cover my garden, if I am reading the dimensions correctly.

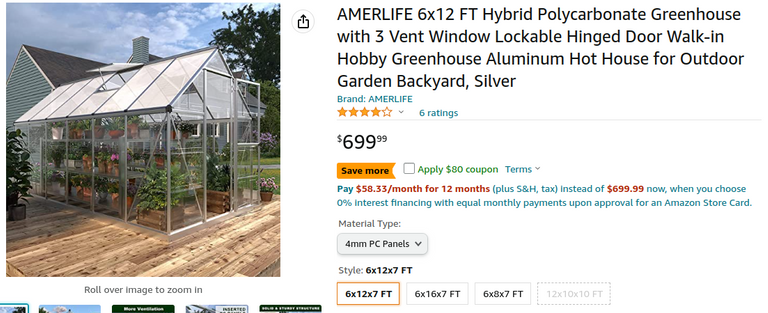

Here's one from amazon slightly smaller than burpee's, and a tenth of the price.

I mean, if I heat it up during the winter it would probably suffice for some of my tropical plants. but this covers about 2% of the area I would like. The seller notes that it can only handle up to a 56 mph wind. It also doesn't look very ideal to anchor in the ground.

There are many in a similar style. They also have hoophouse greenhouses, and even geodesic. But the later is not ideal to chain together. Many of Amazon's inexpensive results looks flimsy, some appear to just be screen tents, or have some kind of green tint to them.

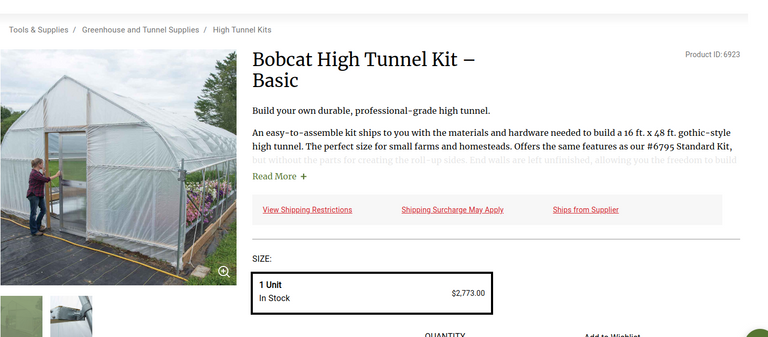

Johnny's seeds has a style that I like.

16x48ft, I'd still need about 4-5 of them and the fit wouldn't be ideal. I just don't think in this solution there is some $2800 in parts, nor the extra shipping. And if that is not enough, the kit doesn't include the baseboards. Even if it had the baseboards, I am not fond of the idea of using steel poles in the ground of wooden baseboards to support a greenhouse. Even Galvanized steel can corrode, and wood against the earth can rot.

So pretty much I don't like the pre-built systems. If I was planning to stay here long term, I might go with a hoop house.

The issues with home made systems are many.

Let's consider the covering:

They are the materials to allow the light in, whether they are glass, plastic solid, plastic film, or maybe someday Alon. The cheapest is the plastic film, it has to be UV coated, and preferable 6 mil. End even more ideal double layers. The drawback is that it rules out cheap PVC as a material, and the film itself only last a few years and needs repair.

R-values of coverings:

This is more a measurement of maintaining heat or resisting heat transfer. the higher the r-value, the better the greenhouse will keep in heat.

The r-value for polycarbonite is .83. Probably the worst choice in terms of r-value, but pretty durable. https://greenhouseemporium.com/blogs/greenhouse-gardening/polycarbonate-thickness-greenhouse/ . It looks to be about $3/sqft at home despot, but there are probably better prices. More importantly, epic gardener reports that polycarbonate leeches BPA. If if you don't want to turn the friggin frogs gay, I would also image you don't want BPA in your food crops. https://www.epicgardening.com/which-plastics-are-safe-for-gardening/

The R value for a single layer of glass is .9, and a double layer is 1.7 https://aerosealcorp.com/understanding-r-values/ . Although it can vary greatly based upon a number of factors, such as the gas between panes. https://www.allweatherwindows.com/the-pros/architect/glass-performance-chart/ Ordinary glass seems to be about $3.5/sqft at lowes...at 3 mil thickness. so $7/sqft for 6 mil.

The r-value for acrylic/plexiglass is .86, but is a stronger material than glass. https://www.plasticsintl.com/media/wysiwyg/Acrylic__PMMA__Extruded.pdf . The cost of acrylic is about $6/foot at lowes.

The r-value for a plastic cover can be as high as 1.7. https://www.globalplasticsheeting.com/our-blog-resource-library/what-is-the-difference-between-6-mil-plastic-sheeting-and-solawrap-greenhouse-plastic . The only place I could find it online and do a quick mental conversion was a little over $3/sqft.

The r value of 6mil polyethylene is .85, and a double layer is 1.25. https://www.globalplasticsheeting.com/our-blog-resource-library/what-is-the-difference-between-6-mil-plastic-sheeting-and-solawrap-greenhouse-plastic . I did try to find some clear uv coated HDPE sheeting, but I couldn't find any that was economical.

Let's go to the support:

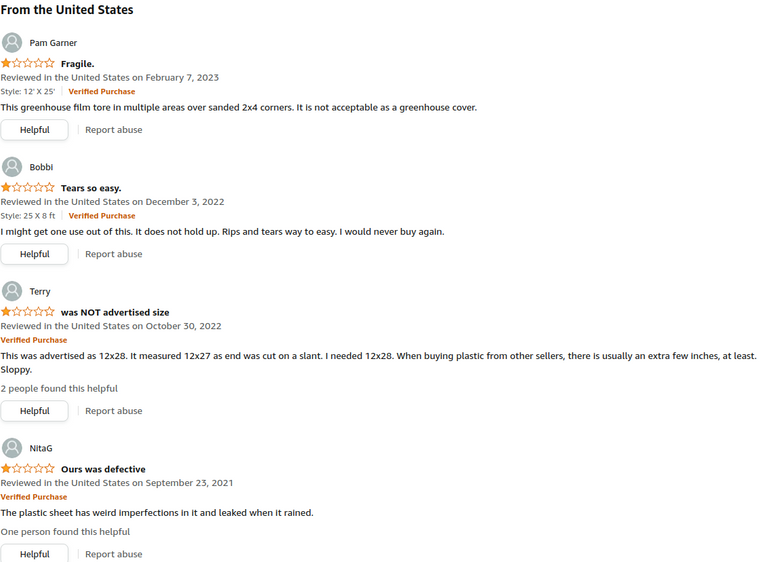

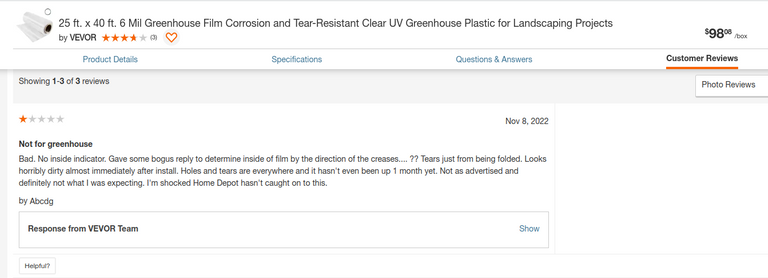

the distance between vertical support structured in greenhouse should be about 2-3 feet. And horizontal supports should be placed about 4-8 feet and connected to the rafters [roof]. https://extension.okstate.edu/fact-sheets/greenhouse-structures-and-coverings.html Price? when shopping, I tend to look at the 1 start ratings. Maybe they could be real or fake, but on Amazon a common theme I see if that it appears it was cut from a larger roll and might be cut too short of have holes in them, or might be somewhat opaque. Let's check a few of the 1 start ratings awarded to an amazon best seller.

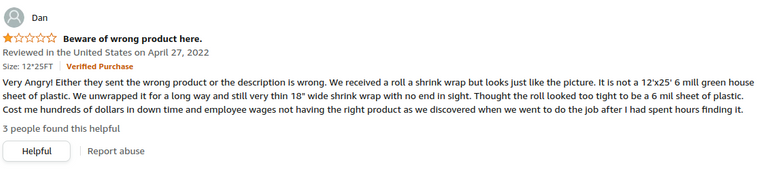

I don't think I'd buy greenhouse film on amazon. I'd rather go to a brick and mortor and see what i am getting. Here is what allegedly happened to one guy who bought a roll from one amazon seller. Trying to save a few bucks, cost him much more.

So it appears to be a take a gamble at amazon for about 9 cents/square foot (or double if you want the 1.25 r-value).

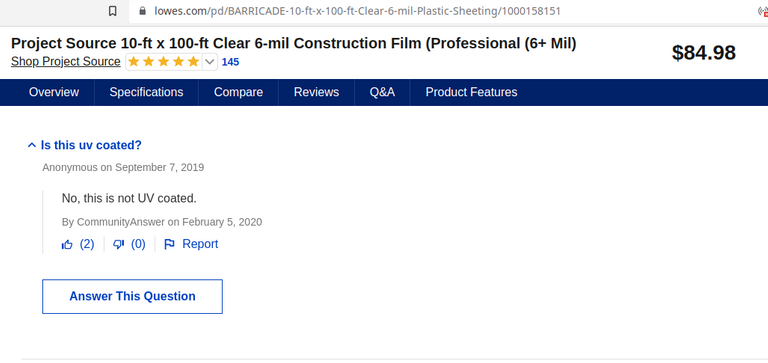

maybe Lowe's?

I am not sure who "communityanswer" is, but certainly neither Lowe's nor the manufacturer cares enough to dispute this claim. So Lowe's is an obvious no. Menards sells twice as much for a little bit more, but again no uv coating. So again, garbage as greenhouse film. Tractor supply? Nothing i could see that is uv protected, but they do have a lot of greenhouses that I have no interest in. Walmart, again nothing that is uv protected.

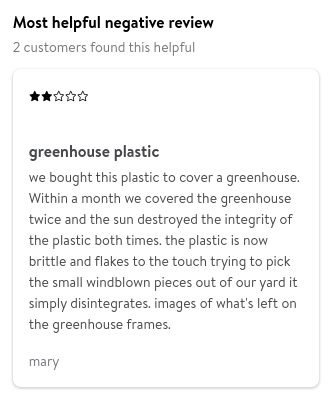

Home depot has a few hits, let's check the reviews.

And of course, after all this, it leaves me wondering where I can really get greenhouse film? I mean there is johnny seeds who offers something called tufflite IV. It's about 50% more expensive than ordinary polyethylene, and they sell 4000 sqft at a time. Yes, this does react to PVC and voids the warrantee. There are other retailers selling tufflite IV, but I am not familiar with them. One site says that wood treated with ACQ also voids the warrantee; but I haven't run across this for ACQ treated wood and polyethylene in a more general sense. But anyways, the size greenhouse I would consider probably would consume two whole rows and some change; effectively putting me back some $1500-1800 just for the film. And who said this is any better than what everyone else sells as greenhouse film/plastic?

how about adding your own uv coating. While there is chatter that there is a coating that can be put on polyethylene, much of the discourse seems to be adding compounds why the polyethylene was still in a molten state. There are too many sites that want to treat the reader like a 8 year old and won't go into the fine details. https://phoenixplastics.com/uv-stabilization-protecting-plastic-resins/

As an added bonus, dried epoxy resign reportedly has an r-value of 7....but degrades in the sun and high humidity. Supposedly 1 gallon of epoxy resign is 231 sq inches. So basically a gallons could produce 6 1sqft panes a quarter in thick. At about $60/gallon, that is about $10/sqft. Seems like a lot of work

Support structure?

PVC?

So if 6 mil uv coated polyethylene film is used, that pretty much rules out using PVC pipe. Not that PVC pipe is ideal, it can only be expected to carry a 28 lb load. however, pvc should be pretty stable in the ground and could last hundreds of years. https://www.thehealthyjournal.com/faq/how-long-does-it-take-for-pvc-to-decay

Wood?

Weed is subject to rot in the elements, although certain hardwoods like cedar may be better. One site claims that using ACQ pressure treated wood voids the warrantee when used with tufflite IV, and I don't think it is unreasonable to consider ACQ might adversely affect polyethylene in general.

Aluminum: Aluminum is pretty stable once it has an oxidized layer. It is however subject to corrosion when exposed to salts or other metals, including in the ground. https://www.wileymetal.com/aluminum-corrosion-why-it-happens-and-what-to-do-when-it-does/

Cattle Panel:

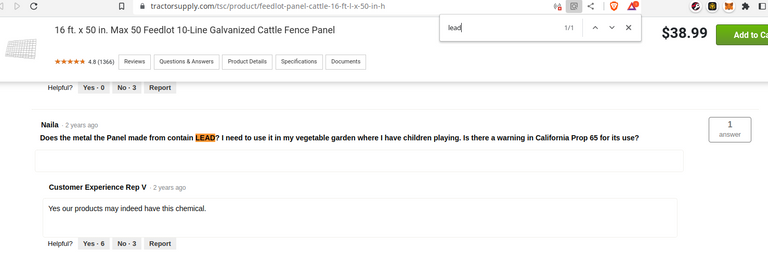

Hell no. It is quite common to see videos of people making greenhouses with cattle panel. For metal it is pretty stable, and bendable, and you can pick it up from tractor supply. Cattle Panel can resist corrosion better than galvanized steel if it was given a layer of chrome. Chrome is a red flag, particularly because it also uses lead.

I am not sure if the lead is dangerous in these quantities. But if the goal is to eat healthy foods, or sell organic foods, I would stay away from this.

vid source: Dave the Flip Flop Farmer

That guy went to tractor supply to get his cattle panel. What does the tractor supply Q & A read?

Yikes

Glavanized Electronical metal conduit: One thing to look into is to see if galvanized EMC has an extra layer of chromium. If it has chromium then it has lead. Galvazined steel is rust resistant, but can still rust if anything penatrates the zinc layer.

anchoring to the ground:

I think I've seen a few types of grounding a greenhouse to the ground.

From the johnny seeds we see a galvanized steel pole being inserted into the ground. My concern would be that the steel would rust.

Some appear to just lay flat on the ground, which many people just attribute to the kits, like the Johnny's seeds kit, not provided the baseboards which they have to build themselves.

So at that point it appears that after the baseboard, which probably should be cedar, is created there is a choice of using various types of stakes to try to hold it in place, or create a concrete base on or into the ground, and anchor bolt the frame to the concrete. Another problem is that even in a home, 10% of the heat lost is through the floor. It's going to be a lot worse in a greenhouse at merely ground level.

Heating:

One thing I see many people do in videos is just run an extension cord to the greenhouse to control the heat with sensors and portable heaters.

There are alternatives, besides solar panels and solar batteries, including a heat battery. Of the types I see, but know little about, are: geothermal/earth/climate batteries/[subterranean heating and cooling system] that pushes air underground with fans to be passively heated or cooled; Underground water storage tanks; and to supplement a solar panel a sand battery where excess electricity generated by solar is used to heat up sand.

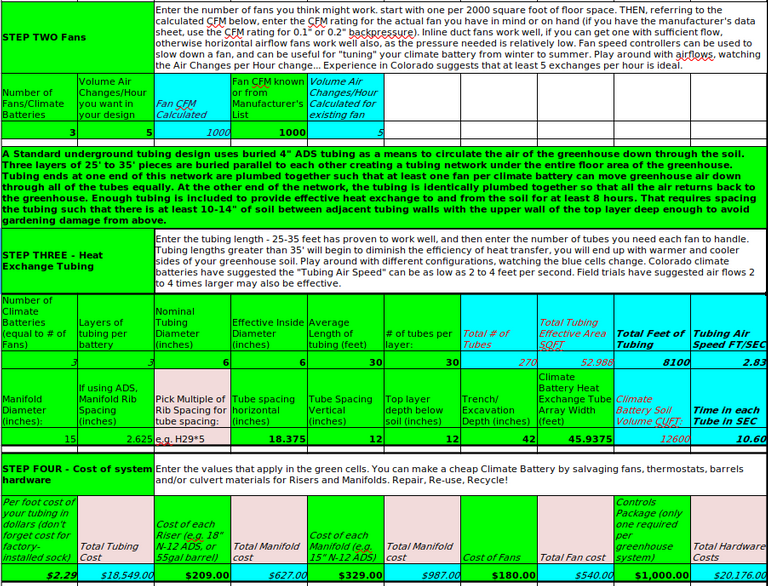

the geothermal energy model has the best documentation, complete with air flow calculations. Here is one calculator, it is a bit confusing to use, IMHO, and it is possible I messed up my calculations.

One thing I've read is that certain fans, a so called squirrel cage type, will burn out. http://www.ecosystems-design.com/faq.html . They type they recommend is a horizontal airflow type. The problem is when you search amazon for the horizontal air flow type, the top results seem to be squirrel cage types. Another problem is they don't work well in clay soil, or when the temperature drops too much.

As I played around with the calculator and checked prices, I think i am seeing that the cost of the manifold might be for a 20 foot length of ads tubing. So for a 90'x40' garden with say a 10' ceiling, or whatever mine is or will be, with 3 climate batteries, I am looking at a $20k price tag just to put in the system.

Of course there are additional expenses, like joining the material, and cutting the material. Then there is a backup heating solutions; saunas have been suggested, which are 3-6k each. And the cost to rent an excavator would be roughly $300/day or $1300/week. And about $200/day or $700/week for a tractor to fill in the hole.

So using a climate battery option could cost $30k in upfront costs.

As far as sand/water batteries, it just isn't clear what size they should be and what temperatures they should be set to say to get through the winter. it seems raising 4 pounds of air one degree is raising 1 btu. 13.3 cuft of air weighs about 1lb. So 1BTU raises the temperature 1 degree for about 55 cuft of air. The greenhouse would be about 3600 sq ft. If this was an insulated home, I might need a heater with a capacity of 72k BTU. https://www.pioneerminisplit.com/blogs/news/how-many-btus-you-need-for-your-room-or-house But this isn't a home, and it has a lower R-value, and might need 144k BTU capacity or more. But that is only a measure of capacity, not a measure of continuance heat throughout a season.

There are about 9 months with a high risks of frost here, but let's just say we want to raise the temperature 20 degrees 3 days these months-on top of any warming effect (about 8°F) the sun already has. of the remaining 6: lets say 6°F for 12 hours for 30 days, and 20°F for 12 hours for 30 days; 19°F for 12 hours for 31 days, and 33°F for 12 hours for 31 days; 23°F for 12 hours for 31 days, and 40°F for 12 hours for 31 days; 19°F for 12 hours for 28 days, and 37°F for 12 hours for 28 days; 10°F for 12 hours for 31 days, and 27°F for 12 hours for 31 days; and 16°F for 12 hours for 30 days. so about 94428°F x hours.

we see that, from https://neo.ne.gov/info/neq/neq-archive/2017-09-sept/sept2017-07.html , U-Values=btu/(hr x sqft x °F) & R-Values=1/U or hr x sqft x °F/btu. We know from the surface area of a boxed greenhouse [for faster math] 3600+2 x 10(90+40)=about 6200 sq ft. So the numerator is 585453600 x °F x hours x sqft. We are going to assume a double 6 mill polyethylene will be used, or r=1.25. So y btu=585453600 x °F x hours x sqft/1.25; y=468362880, or about 137263578 watts. Let us also consider an r-value of 7 to capture the other extreme, btu=585453600 x °F x hours x sqft/7=83636228, or about 24511353 watts. 1 btu is how much energy to raise 1 lb or water 1 degree. So lets say we want our water storage to be near boiling, an extra 150+ degrees; well in our polyethylene house that is over 3.1 million pounds of water; there are about 62.41lbs of water in a cubic foot at room temperatures-and no I am not going to consider thermal expansion [or shrinkage as water loses oxygen], so maybe 50000ish cubic feet of water; Of course, a water storage tank will also lose/radiate energy out and that would have to be figured in as well, but that isn't practical. In our best efficient greenhouse, we might still need about a 9k sqft storage tank. Sand is only about 20% as efficient at storage energy as water per weight, but a sand battery is often heated up to 1050°F and is 33-60% more dense. Starting with the double polyethylene covered greenhouse, we only need some 2341k lbs of sand. Let us also say there is 90 lbs of sand per cubit foot. well we are down to about 26k cuft of sand. we might as well say 4560 cuft of sand in our energy efficient home. The volume is about 50% more than the 8MW polar night cylinder, yet supposedly can store 24MW. Maybe polar night only heats theirs to 500c, maybe it is an efficiently loss, maybe it is a calculation issue. But even if it should be twice as good as polar night's,, sand is about $20/ton in 2023. https://spendonhome.com/ton-of-sand-cost/ Even before delivery considerations, the sand is going to cost some $47k. This doesn't even consider how to heat the sand, nor what materials to insulate the sand. Oh yeah, you still have to bake ($0.15/kwh)some 24MW of electricity into the sand, which would be another $3600.

Space heaters? Space heaters on amazon, with the exception of the 60k models, tend to be about $100/40kBTU....but those are gas powered. But there are 5k btu, 1500 watt, electrical units for $40. well if I need 30 of them, , and for each one of them I need at least 15 100w solar panels at about $1/watt, and power inverters, solar batteries, I don't see that happening also. How about using the good ole power grid. 30 x 1.5kw x 24hours/day x $0.15kw/hour=$160/day at full capacity. Eh, why don't we just look at our efficient greenhouse that uses $3600/season. And uh, never leave a space heater unattended; that's a good way to cause a fire.

In a pre-published final edit, propane heaters are cheaper than electric heaters.

So maybe after all this, the solution we are looking for isn't a greenhouse. maybe we should just build a concrete warehouse and use grow lights. The drawback is of course the greatest probability to have to get a permit or pay property taxes than an ordinary greenhouse. The r-values are additive. https://www.archtoolbox.com/r-values/ , so we could just stack layer after layer of insulating material to get the desired energy savings results-at the detriment of the upfront cost. Lowe's sells 30sqft of r-30 for about $72. Basically $2.4/sqft of surface area. So if the surface area (less the floor-should the floor be insulated-maybe that can be explored some other time)) is about 6200sqft, its going to cost about $15k in insulation. just for the first layer. You could subtract a little cost out for inserting 2x8x10 studs, for which there will be some 132 just on the walls which would cost some $1700 extra (12.88 each), and probably some 230 2x8x8 studs on the ceiling for another $2630 [also worth mentioning, an optional $2630 lumber for the floor, and $8640 for the r-30]) . How about adding on a roof so the snow can fall off, lets say a 30 degree slope so we can put the bananas & trees in the middle? that will add another $460 in lumber, using 230 2x8x10 in lumber, and another $1800ish in insulation?And so what should we put on the outside? concrete and how thick? concrete is about $100-200/cuyard, or about $11-22/cuft. https://www.bobvila.com/articles/concrete-cost-per-yard/ Let's do the walls, say 6 inches thick. so the walls cover 2600 sqft, a half foot thick wall would make this 1300 cuft. so about $13000-26000. How about the inside? dry wall? https://www.angi.com/articles/what-cost-install-drywall.htm $2750ish for the walls, r-value.45, . Optionally for the floor, 3600 sq feet of 4 inch concrete? another $12-24k? what about the material on the roof and optionally the floorboards? pressure treated plyboard and shingles? The plyboard is about $1.25/sqft. $4500 for the floor, and maybe $5200 for the roof? The roof shingles? 90ft x say 46ft x 4/sqft=16560. https://porch.com/project-cost/cost-to-install-a-shingle-roof drywall on the ceiling, $2000. definitely should be undergound enough to take advantage of passive heat, and even if there is no floor some vertical protrusion to keep rodents out so maybe 134 2'x3' galvanized steel sheets at $15/each, or $2000 minimum for the floor.

Oh yeah, also the space between the walls and the roof. A isoscles triangle with a slope of 30 degrees makes this simple. there are 2 sides where this segment occurs. The area of a triangle is base times its altitude divided by 2. the length is 40', and the altitude is 10', so each triangle is 200 sqft. Both segments are together 400 sq ft. 400sqft is also 1/9th of the surface area of a flat roof (3600sqft).

So at a minimum (random rounding):

floor: $2000 (steel panes), and maybe a water pump & drainage.=2k

walls:$6240 insulation+$1700(lumber)+13k concrete+$3000 drywall +corner_supports+door+support beams+lumber+garden_hoses/water_pipes=23k+

ceiling:2000(drywall)+$16500(singles)+5200(plyboard)+$2200(studs)+10k(insulation)=35k

misc: $200(drywall)+$440(concrete)+$300(studs)+960(insulation)=2k

$1300 heavy equipment rental

min total:63k+

And wait, we're not done yet we've effectively reduced the total area of the greenhouse by 2 feet on each side; so it is a 38x88 internally. Let's suppose a row of crops is 1 foot wide, and we want 2 feet between spacing. Let's suppose the center is 5 foot for a tree. at 5 rows, we are 15 ft in, we have 5 feel for a tree, and then 5 more rows. This is using roughly 35 feet, or about 90% good use of space.

alternatively we could make use of metal shelves, widen the distance between rows to 4 feet, and use 4 shelves per row. we we could have the equivalence of 12 rows of crops, followed by the trees, followed by 12 more rows of crops.

Let us also assume 15 feet between trees or bananas.

In the first model we would have 880 sqft the crops, and in the second model we would need 2112 sqft. a plant needs about 2-3k lumens per square foot. An led light can produce about 100 lumens/watt. https://www.voltlighting.com/learn/lumens-to-watts-conversion-led-bulb . technically that's may not be right, horticulture is more about photons per second or day of certain light frequencies and I am not sure what the relationship is, if any, to lumens. you could get plenty of 9w bulbs for about $1/each, but t5's leds seem to be common-perhaps because some you can link together saving the time and expense. A 20 watt, 2200 specimen, seems to go for about $10/each on amazon. Each is 4 feet long, or about 550 lumens/foot. So you could run maybe 4-5, maybe 6, or these per foot. So just the ordinary rows of crops would run $9k, and the shelves method could run $22k.

Of course there are additional cost for the galvanized steel shelving units, about about 10k, and whatever hold the shelves up-and even the crops growing on the ground only will need something to support the t5 lights.

Let's say a semi-dwarf tree has a 14 foot diameter; it would would take a at least 150sqft if we considered the surface area of a spheroid, it would be over 600sqft. So each tree could be a set back of $1500-6k. And we have 5 tropical trees.

So adding up all these costs, and doubling it is our wattage. Let's say 34kwh. hmm, that is like running 21 space heaters; it's like having a 100k btu heater. Our total insulation cost was 16k, so perhaps it is possible to lower the r-value or used 2x6 instead of 2x8. the rvalue of concrete per inch varies based upon its composition; the lighter the density of the concrete mix ironically the greater the heat resistance. 6 ft of concrete should have an r-value of about .3. So our total r value is about 34. Lets say that on our coldest day we needed to maintain a heat differential of 70 degree above the outside air; there is roughly 6200 square feet of surface area. so in one hour there is 434000 sqft°F. 34=434000/x; x=12764.

Maybe I could have got away with an r-value of 7? I doubt I'll find triple paned glass filled with inert gasses, so lets try instead 8 layers of quarter inch glass. At $56 per sqft I don't have to consider concrete, drywall, a basement, insulation; $56/sqft and a 6200sqft box, oh...$300k+.

Going back to the warehouse approach, the warehouse is going to literally cook-as many other greenhouses do in the summer. Many greenhouses have automated vents. non-electric mmodels can costs about $50 each.

Also there is a taboo about growing crops in the soil in a greenhouse. The coverings tend to block uv rays, which plants need, and the uv rays helps kill bad things like viruses. This is probably why there are so many growing on tables, or in really high raised beds, is to protect the soil-and adds a further cost.

I like the idea of a warehouse, and I would hope whoever pours the concrete uses rebar. But even supposing they do add rebar, I am not sure if the building would be stable. Although I am sure with searching I could find and answer, It would most likely call for a structural engineer. In the absence of a structural engineer, a quick solution would be to create posts [or rooms] to distribute the weight.

After entertaining this idea, I considered the idea of storing water or other liquid underground in some kind of bladder, then forcing it up when it is really needed. The problem with that approach is that many liquids are flamable, water itself expands and freezes, mixing additives to water doesn't achieve much-or when it does it is highly caustic and a leak would mean you are salting your soil. https://www.engineeringtoolbox.com/specific-heat-fluids-d_151.html There are ways of storing aqueous calcium chloride, https://www.oxycalciumchloride.com/sidewalk-ice-melting/effective-ice-melting/how-to-melt-ice-effectively/storage-and-shelf-life such as in certain plastic or certain types of aluminum. I am more curious about ALON's (aluminum oxynitride ; the star trek clear aluminum) potential to hold aqueous calcium chloride, but it seems near impossible to find ALON for sale to test it out short of asking to buy a sample from the sole manufacturer.

As a for final consideration, I thought about greenhouses that sit on hydrolics, that during the winter months could retract in the ground so that there is less surface area. However, It might be more practice to have a greenhouse that say has 4 layers per wall that can be slid up and down, so that in the summer months a wall could stand 8 ft high, and in the winter months the walls would stand roughly 2 ft high and the thickness of the wall would be 4x as thick when in its down position. I can't imagine this could support a large greenhouse due to structural issues and for human limitations. I mean if all the weight of a greenhouse comes down to say a single bolt in a strut channel, what is a reasonable weight without risking severe injury? of the material that might be used I am looking at strut channels, window tracks, and door tracks. The door tracks were too weak, and I will assume this is true with windows. A 24" section of unistrut p6000 can support up to 170 pounds. https://www.unistrutohio.com/p6000 Let's say 3 24" section per post (or 8 for the corners), and each 12" section weighs .36 lbs. https://www.unistrutohio.com/Content/Images/uploaded/P6000.pdf . If you have 12 posts, and 4 of them are corners, we need (12+4) x (3 x 2)ft that's 96' x .36lb/ft. So roughly 36 lbs or struts. 2x4x8 cedar [and we will assume not ACQ treated] weighs over 6.72 lbs, so just the 12 support beams on the walls are 80 lbs-which is a bit heavy. https://roofonline.com/weights-measures/lumber-2x4-weight/ . Another site says a 2x4x8 cedar board can weight 10.9 lbs. Supposing 1x2x8 could be used (and it may not be structurally sound),we would still be looking under 32 lbs-and because our lumber will likely have to be larger than the struts, let's add 25% to the weight up to 40. There would be another 10.9 1x2x8's for the A-Frame roof, So 30 lbs. 36lbs [channel]+30lbs [roof lumber]+40 lbs [wall lumber]+28 lbs [double 6 mil polyethylene]=134lbs. There will still be some extra weight such as bolts for sliding, fasteners, and making appropriate seals.

I can't see that any local vender sells solid p6000 or anything similar to it. It's basically taking a gamble on some websites I never heard of (about $4/ft normally), or trying to get a quote from the manufacturer. Ignoring the baseboard, it will cost about $400 in struts [doesn't include shipping], and another $270 in lumber, maybe $200+ in polyethylene....to cover 120 sqft. and I would need 30 of them? There is some room for savings, if it could be done air tight, by effectively making them long tunnels. But really, will $400 [or $12000 for the 30] for some struts cover the energy savings? Using http://www.littlegreenhouse.com/heat-calc.shtml , going from 501 sq ft, an avg 28 degree temp diff over 6 months, and an r-value of 1.4 (inverse .714) we'd use 43 gallons/month of propane. Going down to 237.2 sqft, same temp diff and time, with an average r value of 2.95 (inv of .338), it would use 20 gal/month. if we consider just .5 inches of trapped air in the walls, same surface area, same time diff, r-value of 3.6 (inv .2758) is about 16 gal/month. A gallon of propane is about $2.70 nationally, so about a $54/month savings if using propane.. That said, the r-value may be a bit inflated, and trying to seal the cracks may add extra costs.

All that said, there might be better things to do before planning a greenhouse. That might involve seeing if there is a cold hard variety, or a dwarf variety, or something cold hardy in the same species in which the desired plant can be grafted to, or something that can be over wintered-whether growing live in a basement or going into a period of dormancy. There are for example red haven and reliance peaches that can grow in zone 5 (possibly 4), so they aren't just a Georgia thing. There is a javid's iranian almond I have been wanting for some time, reportedly a zone 5 almond-but there is no place left to buy them online. Both almonds, peaches (which only live about 7 years), and cherries are in the prunus genus, so i am curious how well a warm weather almond variety scionwood will fair if it is grafted to a cherry tree up north.

For those who want to grow sugar cane, that's an interesting story. There are at least two types of sugarcane, those in the saccharum family which we all know of as growing in the tropical zones, and then there is the sorghum [chinese sugarcane] which is cold hardy. one rarely produces seeds and you'll have to but segments of the cane to propagate, the other is 99.99% is the disappointment you'll get if you order sugarcane seeds online but is cold hardy-even grows in Wisconsin. But there is still cold hardy varieties of Saccharum that grows wildly in zone 6, possibly zones 5, such as Saccharum ravenna, s. brevibarbe, S. giganteum, s. arundinaceum. see

https://www.wetlandplantsinc.com/species/Saccharum-giganteum-Sugar-Cane-Plumegrass. I can't speak if they have any sweetness sweetness, but reportedly they are a fibrous ornamental grass. Similarly sorghum has some varieties meant just for foliage also. But if it is too cold for sugarcane, and sorghum syrup doesn't sound appealing, you might be able to grow sugar beets. But if you do get real sugarcane, reportedly it can be overwintered. There are also cold hardy bananas too. The ones that typically grows fruit will not grow in say zone 4-6, the ones that do grow there are mostly ornamental kinds that might be grown for their fiber like the musa basjoo. There might be some exceptions,such as the monge[e] banana-which is grown as a gros michels original grown at a temperature of 76 degrees below zero F before being thawed. https://www.npr.org/sections/thesalt/2018/02/07/582466810/a-banana-grown-at-subzero-temps-also-has-an-edible-peel I haven't seen any for sale at this time, and maybe in the future d&t farms will use other crops. When they were for sale, they were about $500 each, and goodness only knows if they could be shipped to America-or what usda zone they are. Kind of a lot of money when you don't know if it will grow where you are.

https://web.archive.org/web/20200924012319/https://www.dt-farm.com/pod

I don't think i'll invest in a greenhouse just yet; Even building the shrinking/expanding 12*10 concept may cost $900 up front, and probably $300/year-and it's not like I could grow any cash crops when it is only 2-4 ft high in the summer. Lettuce is a cash crop, but i doubt i could find a significant buyer, Maybe if there was a better market for some fresh exotic fruit as the cherimoya, which could go for maybe $40/pound https://miamifruit.org/products/cherimoya-box and shipped through the mail. But this is rural no where, not some burb of NYC. To deal with the deer, I guess I need more fencing.

That's some pretty thorough research there.

A very rational analysis of the costs and benefits of using greenhouses.

I note that your discussion does not entertain the idea of using compost to heat greenhouses, which you should. Compost was a critical means of heating peasants had available even when most impoverished, and there are theories that sleeping in compost heaps in Europe is what condemned Native Americans to plagues upon invasion by Europeans. Bacterial activity can raise the internal temperature of a well managed compost heap to 130 F, which is substantial heat available in a winter greenhouse.

Since you are in a rural area, there may be sources of manure that you could acquire in the fall, and compost to produce both heat and organic soil through winter, when the soil could be used to amend your dirt in the spring.

Also, you may not have considered using PVC pipes as the interface with the soil, and attaching other materials to the PVC above ground level, which may enable benefiting from PVC's durability in soil contact with other materials ability to sustain loads higher in the structure. Also, well compacted gravel is just as strong in compression as concrete, and drains much better.

Something I noted was that you did consider using LED's to provide light to crops, and simply building warehouses instead of far more expensive light transmitting materials. One thing that can improve the cost effectiveness would be to add large tanks in which various aquatic species are raised for food. Tilapia, prawns, crawdads, and many more species have been used in this way, and the waste from the aquatic species are fed to crops under LED's, or using sunlight by bubbling the aquarium water up to the plants, which clean it of it's waste products so it can be returned to the aquaria. There are good resources online for aquaponics systems, such as

https://www.nal.usda.gov/farms-and-agricultural-production-systems/aquaculture-and-aquaponics

and many more just a search away.

I am considering putting some greenhouses to work one of my clients has available due to their failing health preventing them from being able to use them after they invested in them. Your discussion really enabled me to properly evaluate their value as installed infrastructure, while the marketing of produce wasn't involved, that is more of a local potential and would necessarily be specific to my region.

Thanks!