Well Hello There Fellow Technicians And Hivers

Now today I've got something especially cool! A six speed Ford Ranger manual transmission and we are going to do a tear down on it! Care to join?

I am quite keen on seeing what the problem in this transmission is since this thing is grinding and screeching like mad when you drive it. Even when the vehicle is just idling it sounds awfully terrible, in fact so bad that I want to say I've never heard any vehicle sound as bad as this one!

Well let's see what we can unravel with this puppy.

Out of all the transmission I've ever done a tear down of this one really likes to be hammered especially so with the stripping, the building well not so much we tend to heat up and lightly tap in bearings and such.

After giving this transmission a proper power wash I threw it on the table ready to do the tear down, this was in the early morning hours since we had to get the vehicle out today. (BTW we were able to finish it up and the client will be picking it up on the morrow.)

Well she's big and she is fiesty and she's got a lot of gears to pull!

There a few things we need to remove before we can split the casings, a lot actually.

The most tricky thing is getting the output flange off, now for us this isn't such a hard job because we are rigged and equipped with a lot of nice tools, that much I can say.

Bossman never slacks with the tools, struggling is not in our dictionary.

Trust me this is not a transmission you want to be opening in the back of your yard.

The whole of the transmission is riddled with these interlocks and when you have no clue what exactly they are it's easy to overlook them and when you go ahead to split the casings you wont have any clue that these are going to break.

Now since I have prior experience with these transmissions I do know which I can keep in and which I need to remove.

There purpose are to lock the selectors in place so that you don't select another gear or two gears at once, so when a gear is selected the gear shaft pushes over them and presses the shaft tightly in place.

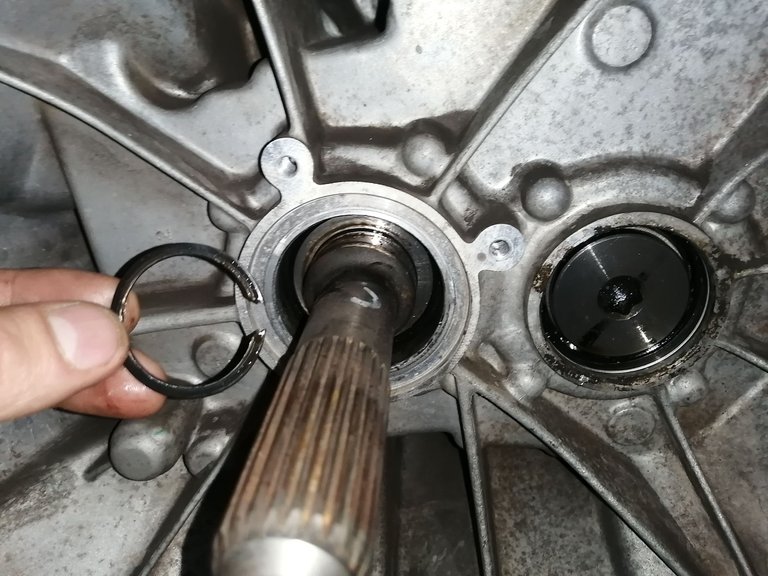

The other tricky hidden circlip is this one here behind the input shaft seal, most people don't know about it, but then again most transmissions have them. I think the reason why people forget these is because they sit behind the seal and most transmissions have a front cover plate that you remove and then the cir-clip is visible.

This is not the case for this build, Ford has to be different!

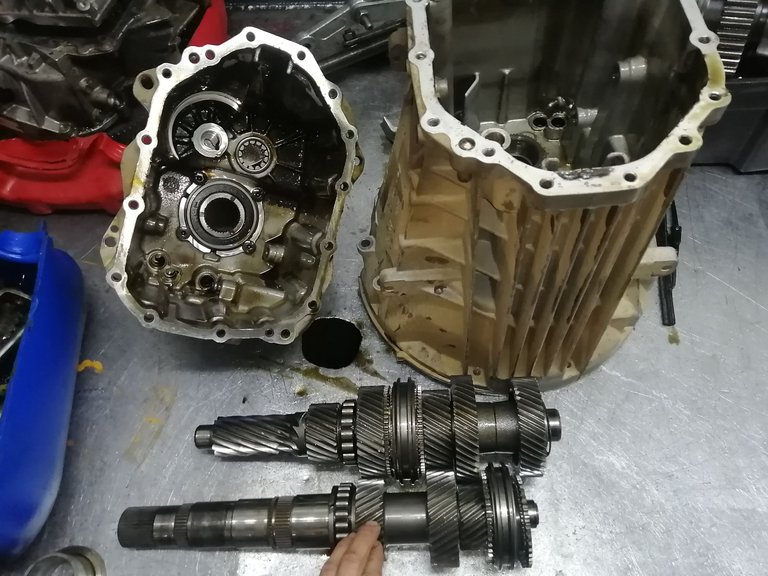

OKAY, I finally got most of the small petty stuff out of way and removed the bolts holding the casings together and ultimately the whole of the transmission!

BTW, they had a lot, I think like twenty bolts on that small patch! Unbelievable, I think Ford has a fear of things falling apart because they really add a heap of bolts where less could really have worked just as well!

Sorry for the blurry photo.

So what I did here was I split the casing a little bit (In the image it's already fully removed so don't work from that.) But I split it a little bit only enough to get the tips of the tire levers in and then I had to hammer the output shaft while pressing the casings from each other.

Yeah a job where three arms would have worked wonders! But never the less I managed!

OKAY, I got the casings off and this would be the very first glance into the transmission and what I saw would ultimately give a very clear indication of how badly damaged it actually is.

One would say this transmission is completely bonkers right?

Oddly enough even with all those metal shavings and a ball bearing added up in the mixture their this transmission was still very damn beautiful!

Why would I say this? Well by the looks of it, it appears to be only a bearing that collapsed.

The magnet sure did it's work above and beyond. If not for the magnets placed inside transmission this one would have been a write off.

See what I meant when I said it still looks pretty damn beautiful... It's almost the same as not judging a book by its cover.

The best part of it all is the fact that no teeth were broken off and neither did the gears mesh into each other. Which is surprising since the bearing collapsed and the cluster shaft was basically loose inside the transmission.

This guy either got lucky OR he got lucky.

I mentioned earlier that you need a wide variety of tools, now a bearing puller or just a puller isn't really all that special of a tool. What is special about this one though is its size, it's huge!

You would definitely have had a huge struggle to get those pulled off with a smaller puller.

The last piece remaining before we can finally pull out the cluster shaft and the counter shaft.

For those who know some things about vehicles and what lies underneath, you might find this interesting. Normally giving a transmission a look over you can see the "sandwhich" plate in between the casings of the transmissions. Well Ford had some creativity and they squeezed this "sandwhich" plate inside the casings. I do have to say I kind of like the idea of it!

And we are so to say done with it all.

The casings are ready to go to the wash bay where they would be washed thoroughly with paraffin and the two cluster shafts are going to be properly cleaned with a few cans of carb cleaner 🤣

Again this guy is probably the luckiest person alive at this very moment on the planet, he went from a full rebuild to just a bearing replacement.

I bet he will ask "How even" tomorrow.

The Damage

As you can see the bearing is off center and most of the ball bearings are not even there anymore. This is a common issue on them, however I've not seen such a badly collapsed bearing and with that where the rest of the transmission didn't get ruined along with it.

Laughs.

This is also a common thing that happens, but some of the ball bearings even broke in two.

The ring to the right is the roller bearing cage and boy oh boy that thing got battered to bits! THis is also one thing that doesn't make sense, if that cage looks so battered then this client has been driving this box for quite sometime.

Again luck.

Dated 14/04/2023

Connecting the people of #HIVE across South Africa. #hive

Wow that looks crazy! I've only fixed 1 manual transmission and it was quite the project. However, I ended up buying a complete rebuild kit then taking apart the whole thing just to find a couple bad synchro springs causing 3rd gear to grind. Felt good to know/find something simple. In your opinion, are manual transmissions easier than automatics to rebuild/repair? One of these days I want to tear into a broken automatic to see what's going on in there, and maybe fix it if possible lol.

Yeah more than often it's small problems leading to big breaks...

Well I can't really say... Most people would say manuals are easier to work with and I do understand why because it's all mechanical... Auto trannys have a lot of electrics also and more than often it's the electrics causing problems and then it makes a mechanical fault.

In my opinion I'd say for me automatics are easier because I started working on them first. But they are trickier. you have to have the right spacing in your clutch stacks, thrust washers have to be placed the right way around, the valve-bodies can sometimes be a nightmare to work on. All in all you don't build a automatic and fit it expecting it to be working 100% there is always something more hidden. Oh and if it's a CVT you are planning on opening, before you close it back up prime the pump. 😄 Always prime the pump

Hello.

You may like to know that you are losing curation rewards since these accounts that you curate are blacklisted for identity theft and their rewards have been equalised:

dianamalenka

malayavaleska

minervarivera

nayvethleyva

perlaloreto

rosyloreto

valeskamaya

vitabriana

yuliduarte

Every job you do is impressive and in my country that workshop would be something very rare to see because of its cleanliness hehehehe.

I'm a motorcyclist and I fix all my motorbikes myself and I always first record how everything was in order so that I know when to put it back, and for something that doesn't work there's you tube and I find a video to help me, I don't give money for master, sometimes I fix small car defects, if something doesn't work, I have a friend, a car mechanic, to help me, well done, master, you do it expertly.