VOC or volatile organic compounds are a dangerous group of chemicals that can vaporize at room temperature. Exposure to these particles has a multitude of adverse health effects including increased chances of cancer or copd.

Printing plastic produces these vocs some more than others. I do most of my printing in ABS which produces a voc called styrene.

In order to combat these vocs I did research into on printer filters and I found one called the bento box. It uses a hepa filter from a robot vacuum and activated carbon. I liked the idea but I felt that the design was over complex. So I setout to design my own.

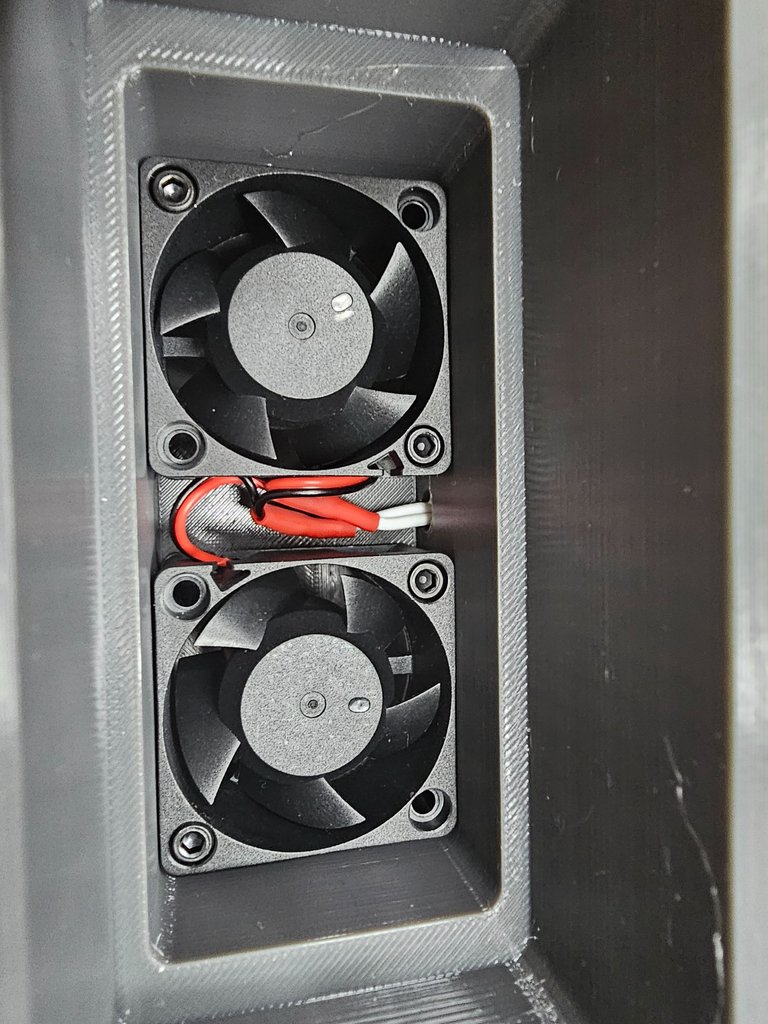

My design consists of 3 parts. The filter, base, and fanbase.

If you want to print one yourself the stl files and solidworks files are on Printables

You will also need.

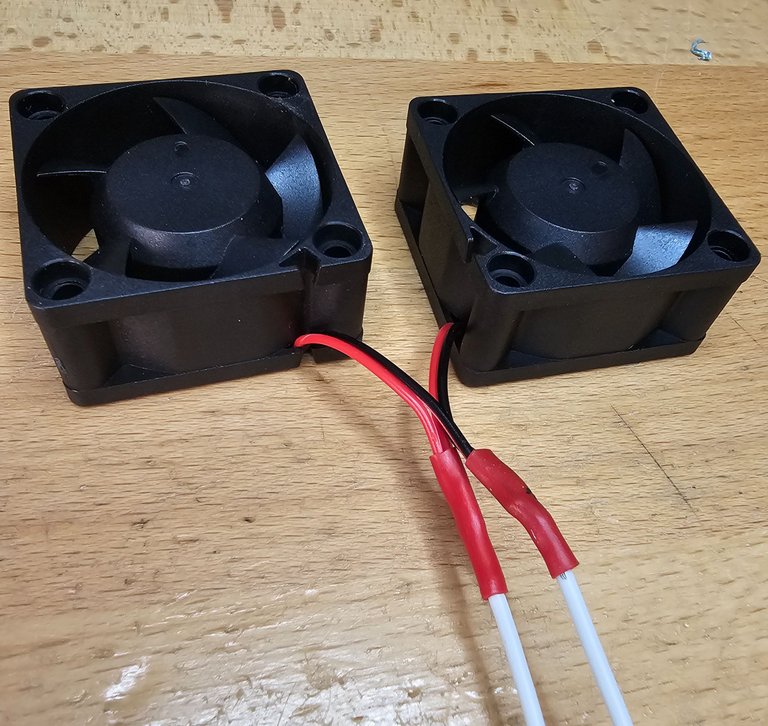

- 2x 40x20mm fans.

- 4x M3 inserts

- 4x 25mm M3 screws

- 2x 15mm M4 screws

- 2x M4 nuts

- 1x 80mm x 40mm x 15mm HEPA filter

- 1x activated carbon enough to fill filter.

By utilizing a mid print pause you can eliminate the need for support.

I print out the fanbase first and add the 3mm inserts to the part. Then I print the base adding a pause to the layer before the overhang. Once the part is started I put the fanbase on the heatbed to keep it warm. When the print stops I quickly added the fanbase to the print and hit resume.

While I was printing I went ahead and wired the two fans together.

Installing the filter.

There are many ways to install the filter. Do what is comfortable for you. This is what I did.

I unplugged and removed the back panel from my printer. Make sure to keep track of which screws go where as some are plastic screws and some are machine screws.

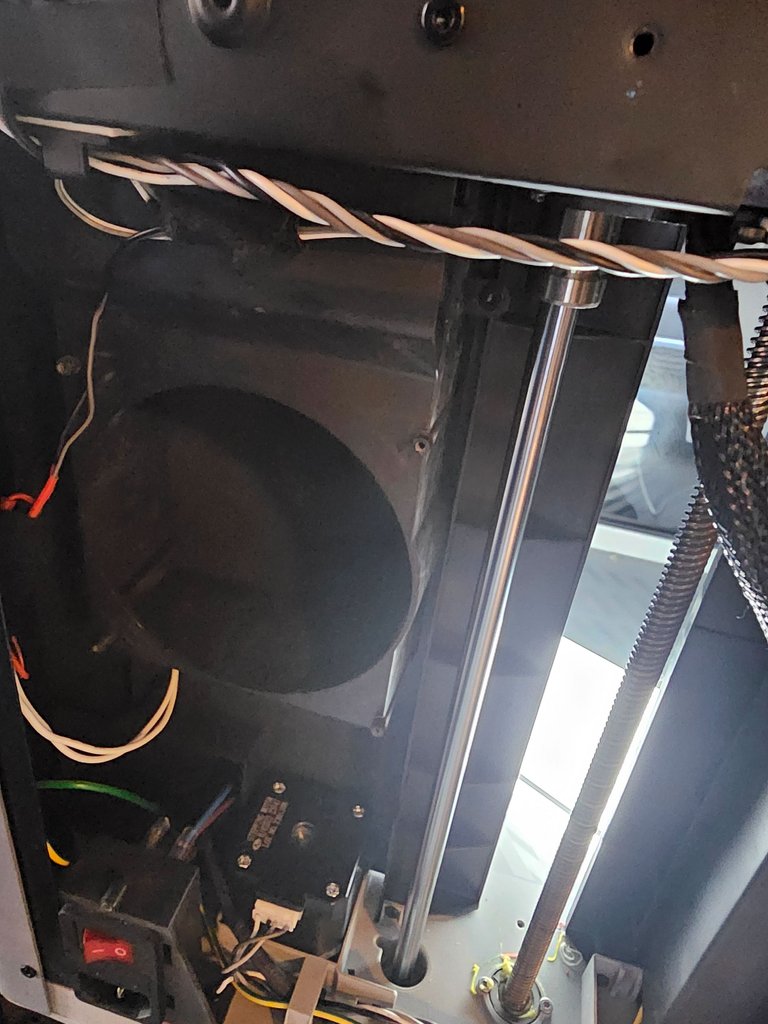

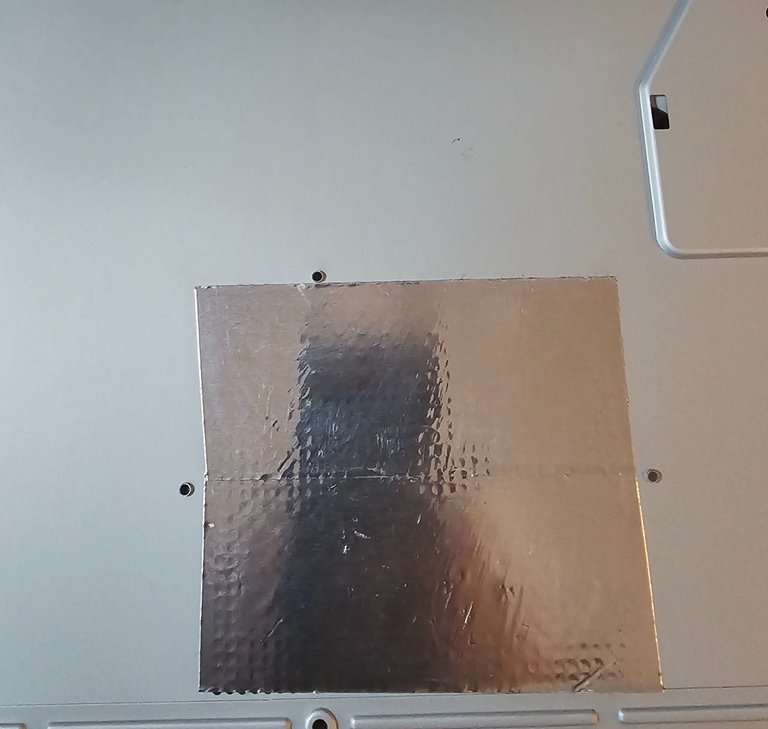

I decided that I was going to remove the chamber vent fan and wire directly into the 24v from the fan connection. I intend to let the filter run 24/7. I also covered the vent holes for the chamber fan.

I marked and drilled 3 holes in the printer. One on the back wall to pass wires through and 2 in the bottom to mount the base.

Once the holes are drilled I installed the fan so it was pulling air through the filter and pushing it out the bottom.

I then passed the wires in, connected them, and bolted the base into the printer.

All that was left was to put the printer together and add carbon and the hepa filter.

I have been using this for a few days now and it has a noticeable impact on air quality. I also have a large hepa filter in my office but it definitely wasn't attending to the stagnant air in the printer. I doubt they are getting it all but every little bit helps.

That's all I have for today.

If you have a chance I would appreciate if you would

This look impressive! Definitely a good idea to take care of your lungs. I only print artsy stuff so not much I can add unfortunately, but glad to see some movement in 3D printing group. Thanks for sharing!

Thanks, it definitely helps a ton. I wish I had made one sooner. I'll be posting more 3d printing stuff soon.