Image source

A blowout is the uncontrolled flow of oil and natural gas from the bottom of an oil well to the surface due to multiple factors, ranging from equipment failure, errors in the supervision of drilling operations, to encountering abnormal pressures in the subsurface due to adverse geological conditions.

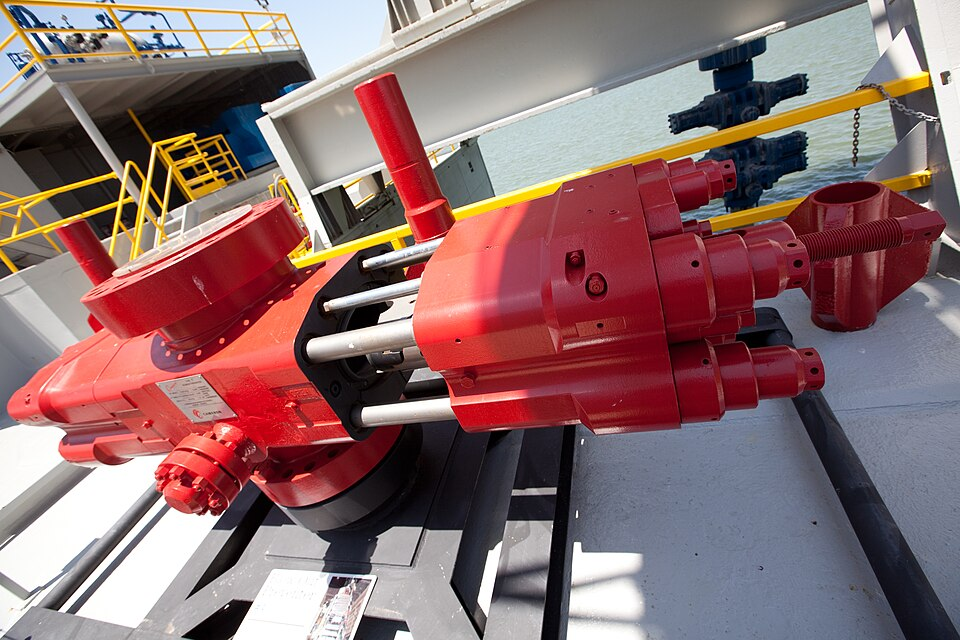

Sometimes the pressure of formation fluids such as gas and oil enter the well but are controlled by a pressure control system that is a set of valves that prevent the occurrence of the blowout, which are designed to the conditions of the well and oilfields to prevent these unwanted events. Below I show a blowout preventer:

The blowout preventer (BOP) shown in the image above is only one type of valve of the many existing ones, there are valves that close to a specific diameter of pipe, and there are other valves such as the annular or spherical BOP that closes to any diameter of the drill pipe.

The objective is to be able to close the well before the blowout occurs and to divert the flow of unwanted fluids such as gas and oil out of the well until the pressures are normalized and to be able to get out of danger, before the blowout if fluids such as oil and gas enter the well and manage to migrate to the surface without a fire occurring, it is because what is happening is a kick, ie an attempt or threat of uncontrolled fluids that can generate a fire on the surface.

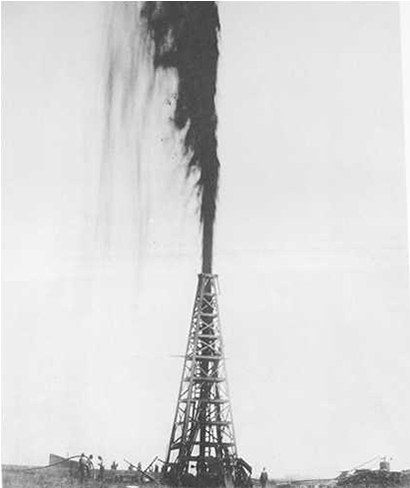

As part of the history of oil well drilling, it can be said that there was not always a pressure control in the drilling of oil wells, since years before 1900, drilling was done with a technique called percussion, which consisted of dropping a pointed drill bit from a high height, there was no pressure control through this technique, since there was no circulation of drilling fluid as it exists today with the rotary drilling technique.

Once the rotary drilling technique arrived, it began to have control over the formation pressures, since through rotary drilling a fluid (drilling mud) is pumped inside the drill pipe that comes out through the jets of the drill bit, this drilling mud generates two types of pressures, a circulating pressure with the mud pumps on, and another hydrostatic pressure with the mud pumps off, and another hydrostatic pressure with the mud pumps off, the latter is the lowest of the pressures that can provide the drilling mud, this last pressure generated by the drilling mud must be greater than the formation pressure so that there is no danger of a kick in the well while drilling, the hydrostatic pressure is calculated as follows:

Ph = 0.052 * Mud density * True vertical depth.

The mud density should be entered in units of pounds/cubic feet, while the true vertical depth in feet.

For the pressure exerted by the drilling mud while the mud is circulating it is necessary to consider the pressure losses due to friction and accessories, although regularly if the mud is circulating, that is to say with the mud pumps on, it should be considered around 200 to 300 PSI additional to the pressure exerted by the drilling mud while the mud pumps are on, it should be considered around 200 to 300 PSI additional to the pressure exerted by the drilling mud when the pumps are off, to have a safety margin it is convenient to drill with a gradient in favor of the drilling fluid of 500 PSI, always respecting that the hydrostatic pressure does not exceed the fracture pressure of the formation.

What causes a blowout in an oil well?

A blowout is caused by an uncontrolled flow of gas and/or oil to the surface, which together with the friction that exists at the surface due to drilling activities causes the fire or blowout to occur.

The influx or kick occurs because the pressure that the drilling fluid (drilling mud) must generate is less than the pressure that the fluids contained in the rock formation (oil reservoir) have downhole, i.e:

Hydrostatic pressure < Formation pressure.

As the mud pressure cannot withstand the pressure exerted by the oil and/or natural gas, then such fluids as gas and/or oil flow to the surface uncontrolled until the blowout occurs.

For future publications I will be covering as main content the signals that an oil well gives us before the blowout occurs, and what we can do to prevent the blowout from occurring once it has already entered the well undesirable fluid such as gas and oil.

Logically, in order to control the well once a blowout attempt has occurred, it is necessary to apply some well control techniques that are typical of petroleum engineering and that I will be explaining to you later on.

References

The Derrick's Hand-Book of Petroleum (Oil City, Penn.: Derrick Publishing, 1898) 20–24.

Wooster, Robert; Sanders, Christine Moor.

Grace, R: Blowout and Well Control Handbook, p. 42. Gulf Professional Publishing, 2003.

I have been against this type of drilling because of the risk it poses to the environment. I do not know if there are ways to reduce the damage to the marine system from spills of this type.

Hello my dear friend @wilmer14molina.

The rotary drilling technique is the safest when taking care not to generate a blowout, because with rotary drilling you can pump a drilling fluid while drilling and thereby generate a hydrostatic pressure to withstand the formation pressure.

On the other hand, percussion drilling was a technique where there was no pressure control and a blowout could occur and spill hydrocarbons without control.

Currently drilling is done with the rotary drilling technique which does not have an impact on environmental pollution, since the burning of fossil fuels is something else, and it is where the environment is polluted with greenhouse gases.

To be opposed to the drilling of oil wells is to be opposed to the drilling of water wells, since the same principle is used, it makes no sense to be opposed to this technique.

If it is not about being opposed to the drilling of wells, but to the production of hydrocarbons, then it is a hypocrisy, because oil is not only used to extract gasoline, the plastic that we all use is extracted from it, asphalt is extracted to asphalt the roads of the world, lubricants are extracted from it that even the asphalt is used to asphalt the roads of the world, It is not a question of whether we agree or not, it is a question of if we do not like the production of oil, then we must find a substitute for all oil derivatives.

So far I do not know of a substitute for all oil and natural gas derivatives that would make it possible to stop producing oil, it is very easy to say I do not agree with this and that practice, but we do not know everything that is behind it. So far I do not know of a substitute for all oil and natural gas derivatives that would make it possible to stop producing oil, it is very easy to say I do not agree with this and that practice, but we do not know everything that is behind it.

The oil spill resulting from a blowout has not been due to the practice of drilling a well, but by negligence of the personnel working, because when drilling offshore should apply the same principles of well control that is used in drilling on land, for example in the spill that occurred in the Gulf of Mexico in the deep horizon platform could have been avoided, as long as you could have taken reading of the signals that was giving the well of the onslaught of unwanted fluids of the formation into the well. By the time they wanted to react it was too late.

Thank you very much for your comment dear friend, I hope to have clarified your doubts.