An internal combustion engine could be likened to the human body in which energy needed is gotten from the internal digestion of food substances. The internal combustion engine is basically an engine in which the burning of a fuel occurs in a confined space called a combustion chamber. The confined space here can be said to be the engine cylinder. A common example of internal combustion engine is found in an automobile

[Image shot from science encyclopedia textbook]

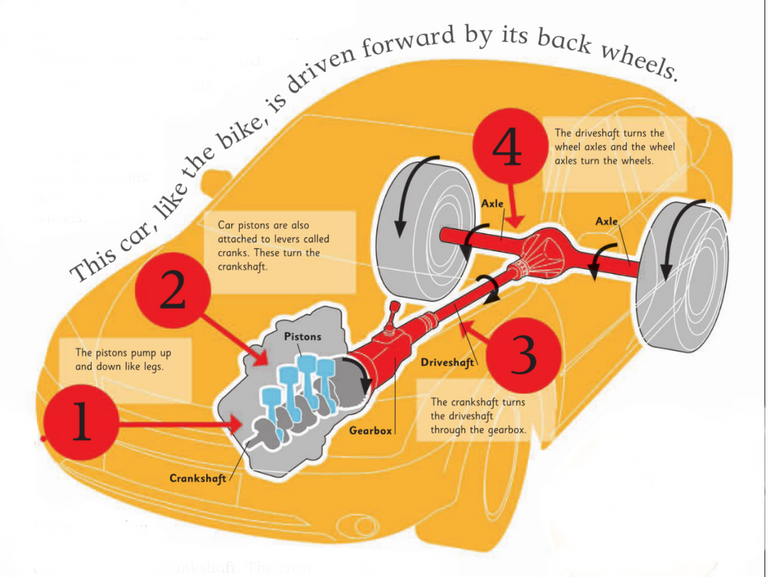

This exothermic reaction of a fuel with an oxidizer creates gases of high temperature and pressure , which are allowed to expand in an enclosed space. The defining feature of an internal combustion engine is that useful work is performed by the expanding hot gases acting directly to cause movement, for example by acting on pistons, rotors, or even by pressing on and moving the entire engine itself.

Parts of an Internal combustion engine

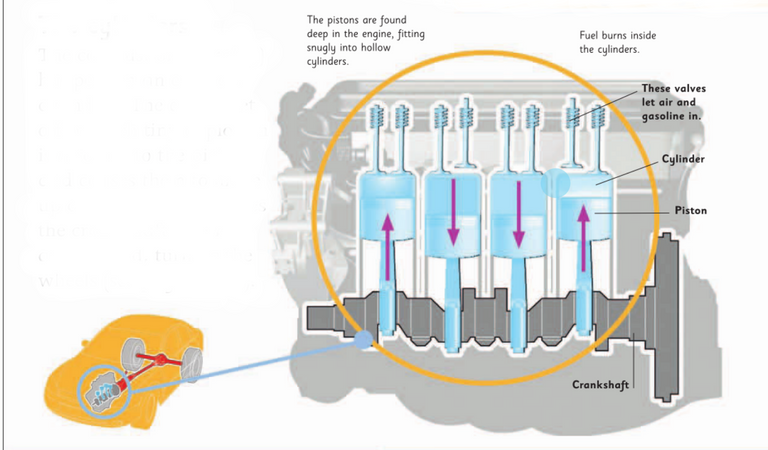

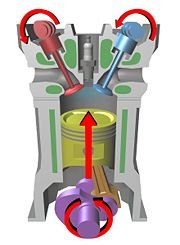

The parts of an engine vary depending on the engine's type. For a four-stroke engine, key parts of the engine include the crankshaft (purple), one or more camshafts (red and blue) and valves. For a two-stroke engine, there may simply be an exhaust outlet and fuel inlet instead of a valve system. In both types of engines, there are one or more cylinders (gray and green) and for each cylinder there is a spark plug (darker-gray), a piston (yellow) and a crank (purple)

Principles of operation

Air-fuel mixture in the combustion chamber (inside the cylinder) is ignited, either by a spark plug (in case of Spark Ignition Engines) or by compression (in case of Compression Ignition engines). This ignition produces tremendous amount of heat and pressure inside the cylinder. This creates a reciprocating motion in the piston.

Power of the piston is transmitted to a crankshaft which undergoes rotary motion. The rotary motion is further transmitted to the wheels of the vehicle , through a transmission system, to produce propulsion in the vehicle.

As the combustion takes place internally inside the cylinder, the engine is called internal combustion engine.

Internal combustion engines ranges from two stroke engines, four stroke engines and five stroke engine.

No matter how many cylinders an engine has 1,2,4,6,12 the same actions takes place in each cylinder. Actions being referred to starts from the intake of air to the exhaust of burnt gases

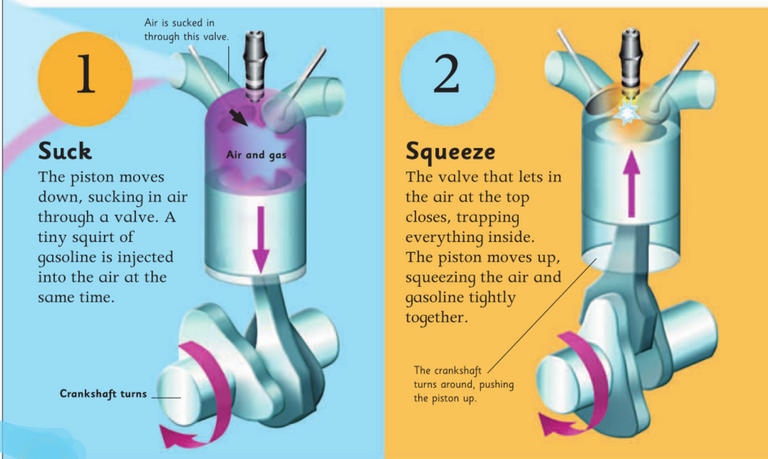

The four stroke cycle (otto cycle) which is the most used comprises four strokes, each stroke playing its role in achieving a complete combustion process. The four strokes include;

Intake stroke: this can also be called suction. Here the piston moves down and the intake valve open. This downward movement of the piston a partial void or vacuum in the cylinder and the air rushes into the cylinder. This action can be noticed when drinking through a straw, a partial vacuum is created in the mouth and the liquid moves up the straw to fill the vacuum.

Compression Stroke: this action can be likened to squeezing the mixture in the confined space. The piston reaches the bottom of the intake stroke and the intake closes. Both intake valves and exhaust valve are now closed sealing the upper end of the cylinder. The rising piston compresses the airfuel mixture. The mixture is compressed to one-sixth or one-seventh of its original volume. This is the same as compressing a gallon of air until a little more than a pint of air is left. Compressing the air makes it more combustible; the energy in the fuel is concentrated into a smaller space.

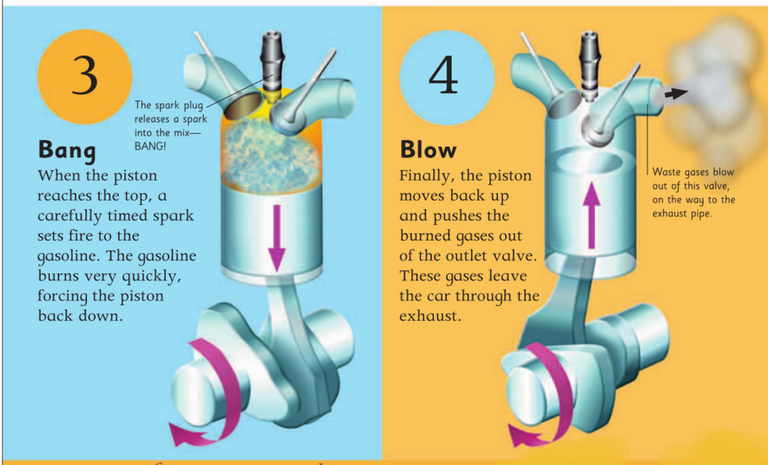

[Image shot from science encyclopedia]Power stroke: At full compression, when the piston is at the maximum upward position, the compressed air fuel mixture is ignited. The ignition system produces a spark in the cylinder causing the mixture to burn. The generated pressure produces a bang and forces the piston downward on the power stroke.

Exhaust stroke: After the air-fuel mixture has burned, it must be cleared from the cylinder. This is done by opening the exhaust valve as soon as the power stroke is finished and the piston comes back up on the exhaust stroke. The piston forces the burned gases out of the cylinder through the opened exhaust valve.

[Image shot from science encyclopedia]

The four strokes must be automatically repeated over and over in the same sequence in each cylinder if the engine is to run properly

Efficiency of an internal combustion engine

The efficiency of an IC engine (Internal Combustion Engine) is defined as the ratio of workdone to the energy supplied to an engine.

The efficiency of various types of internal combustion engines vary. It is generally accepted that most gasoline fueled internal combustion engines, even when aided with turbochargers and efficiency aids, have a mechanical efficiency of about 20 percent. Most internal combustion engines waste about 36 percent of the energy in gasoline as heat lost to the cooling system and another 38 percent through the exhaust. The rest, about six percent, is lost to

friction . Most engineers have not been able to successfully harness wasted energy for any meaningful purpose, although there are various add on devices and systems that can greatly improve combustion efficiency. Hydrogen Fuel Injection, or HFI, is an engine add on system that is known to improve fuel economy of internal combustion engines by injecting hydrogen as a combustion enhancement into the intake manifold. Thus permitting the engine to operate with more advanced ignition timing, a higher compression ratio, and a leaner air-to-fuel mixture than otherwise possible. This results in lower pollution with more power and increased efficiency

The following efficiencies of an 1.C. engine are important:

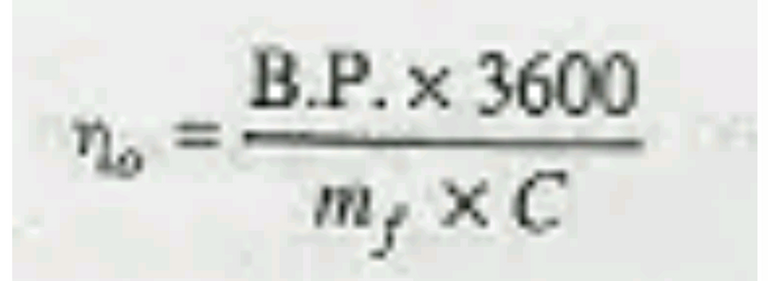

Mechanical efficiency :It is the ratio of brake power (B.P.) to the indicated power (I.P.).

Mathematically, mechanical efficiency,

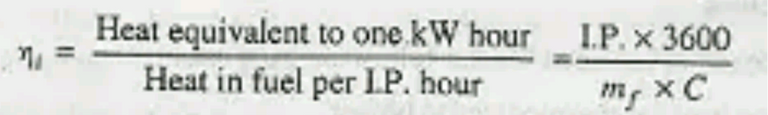

Since B. P. is always less than I.P. , therefore mechanical efficiency is always less than unity (i.e. 100%).Overall efficiency: It is the ratio of the work obtained at the crankshaft in a given time to the energy supplied by the fuel during the same time. Mathematically, overall efficiency,

where

B.P. = Brake power in kW,

mf = Mass of fuel consumed in kg per hour, and

C = Calorific valve of fuel in kJ / kg of fuel.Indicated thermal efficiency:It is the ratio of the heat equivalent to one kW hour to the heat in the fuel per I.P. hour, Mathematically, indicated thermal efficiency,

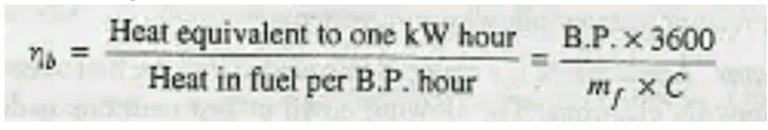

Brake thermal efficiency: It is the ratio of the heat equivalent to one kW hour to the heat in the fuel per B.P. hour. Mathematically, brake thermal efficiency,

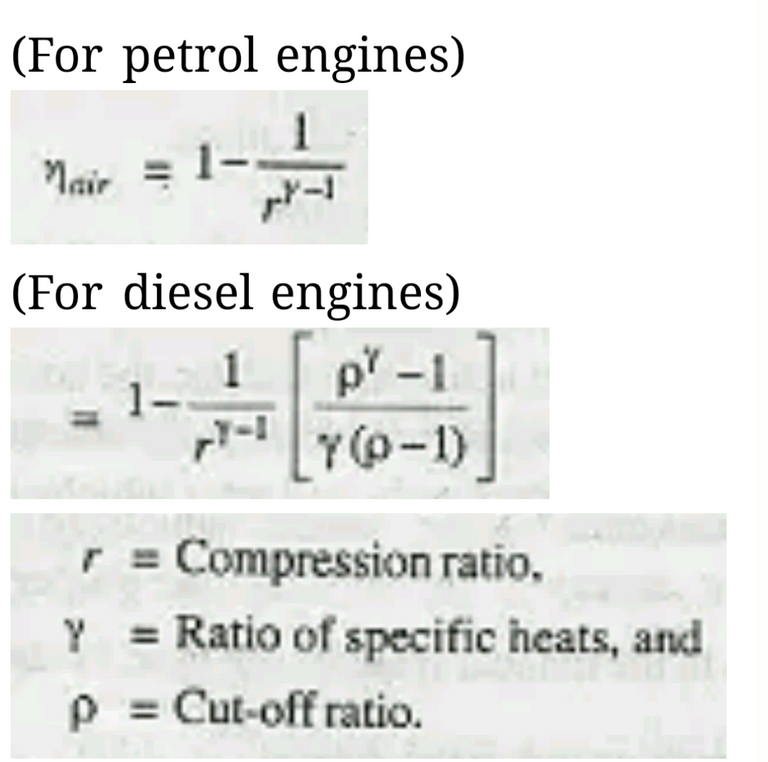

Air standard efficiency: The general expression for the air standard efficiency is given as:

Relative efficiency: It is also known as efficiency ratio. The relative efficiency of an I. C. engine is the ratio of the indicated thermal efficiency to the air standard efficiency.

In conclusion, modern day engineers are diligently working hard to obtain the maximum efficiency possible for an internal combustion engine. Features such as Exhaust Gas Recirculation(EGR) are now installed to ensure complete extraction of energy from the fuel.

Informative post @davyd. Do you think that for the ICE (internal combustion engine) we've reached the peak of miles-per-gallon at 40-50 without making it a hybrid, or could we possibly optimize more? I see claims sometime that we can get more out of our engines, but don't see too many people pulling this off, so it seems we've hit our limit.

Thank you @sqIinsix

I dont think the 40-50 miles-per- gallon(mpg) mark is good enough to be our peak. More MPG heights can be achieved with a more efficient engine and transmission system with a lighter body and suspension(for improved ratio of sprung mass to unsprung mass) . So yes there is still much room for optimization.